The networking of mechatronic systems around the vehicle and beyond as well as the interaction of the fields of mechanics, electronics and information technology are also central to the laboratory equipment. Highlights are the areas of pedestrian protection, vehicle sensors & active vehicle safety and passive vehicle safety. The focus here is on the investigation and development of accident-preventing and accident-detecting mechatronic systems as well as their test equipment and procedures.

Goals and idea

The aim of the laboratory is to provide students with a practical introduction to the research areas of mechatronics and especially vehicle mechatronics. This is achieved by the interlocking of research and teaching activities and the modern equipped workstations, which are not only available for continuous internships, student projects and theses, but also for interesting applied research activities, also in cooperation with international partner universities.The G007 laboratory is closely linked to the C020 laboratory and the CARISSMA research and test centre. This strengthens the interlocking of teaching with applied research and thus enables access to further equipment and test facilities (e.g. high-speed cameras, dGPS, etc.).

Laboratory equipment and activities

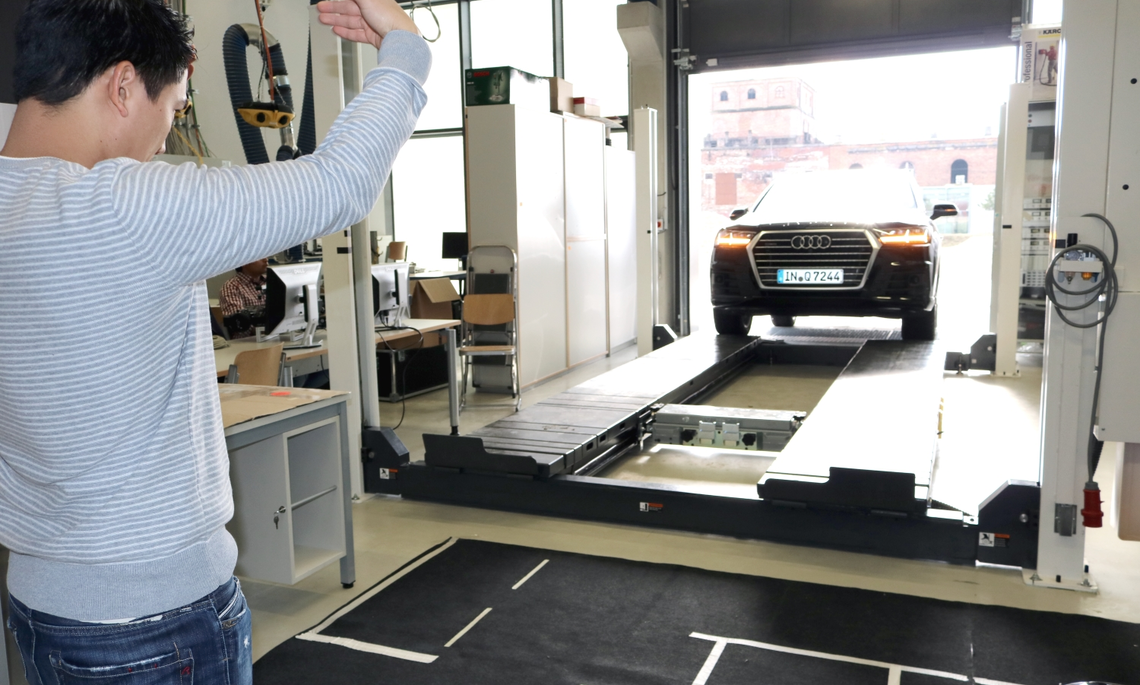

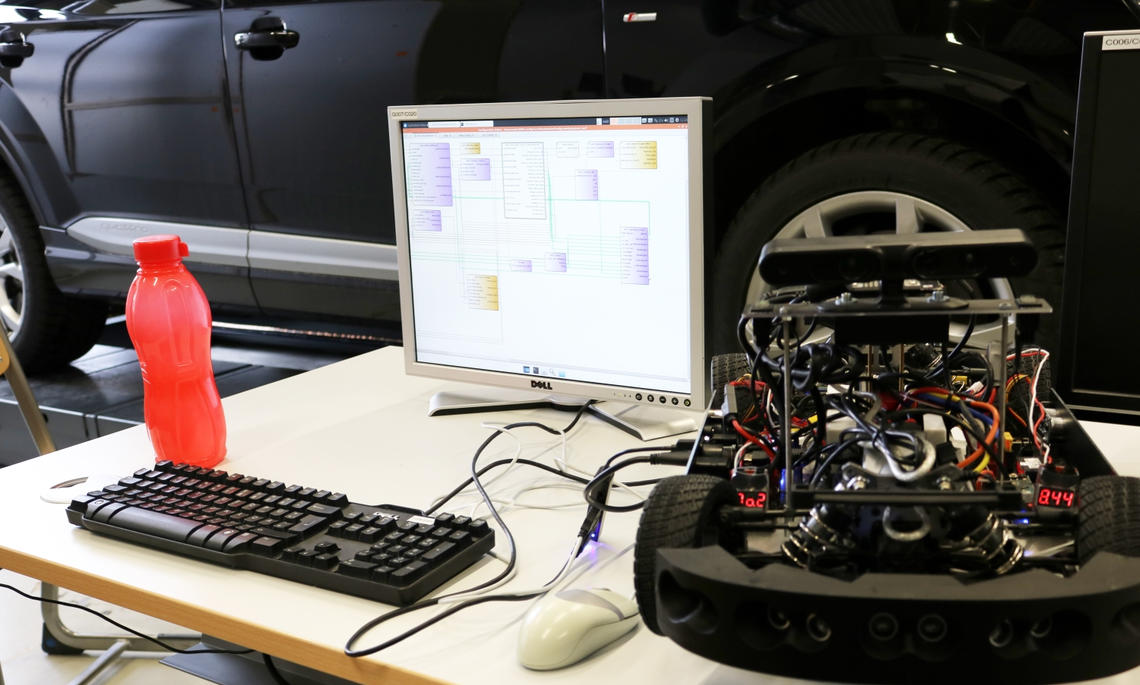

Modern, well-equipped workstations, measuring systems and equipment as well as evaluation and simulation software are the basis for successful studies for students and successful research projects for scientists. In addition, modernly equipped vehicles such as the BMW M5 and Audi Q7 are available for real-life driving and experiments.

Vehicle safety engineering:

- Tensile-compression testing machine Galdabini Quasar 50 (investigations of material and component properties as well as their structure-borne sound generation)

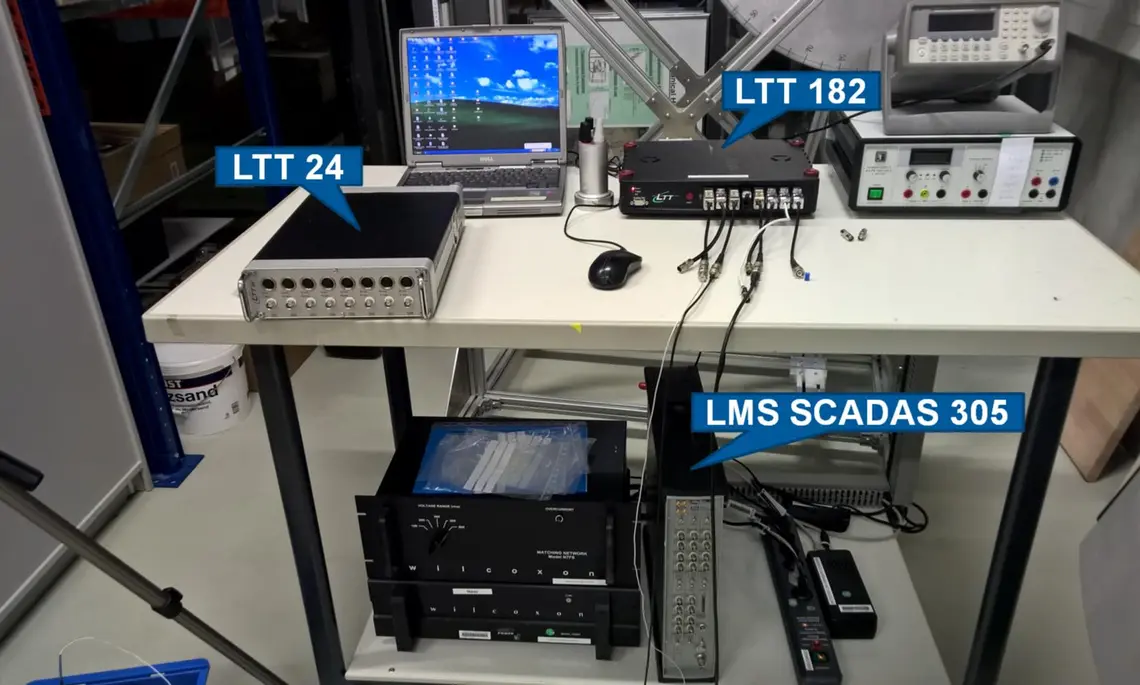

- Data acquisition systems:

- LLT24

- LMS SCADAS 305

- LTT 182 Transient Recorder - Various sensors

- Impact generators:

- Compressed air shooting apparatus for small metal balls (modal analysis and investigations of structure-borne sound propagation)

- Pendulums (various material and impact tests as well as investigations of structure-borne noise generation and propagation)

- Miniature sled system for crash tests (various material and impact tests as well as investigations of structure-borne noise generation and propagation) - Piezo shaker (up to 40 kHz) (modal analysis and investigations of structure-borne sound propagation and visco-elastic absorbers

- X-Sense compact system

- Pedestrian dummy with human movements (THI proprietary development)

- DGPS inertial measurement system ADMA-G eco+

- Rain simulator (with weather station) for the generation of natural disturbances

- Radar trainer

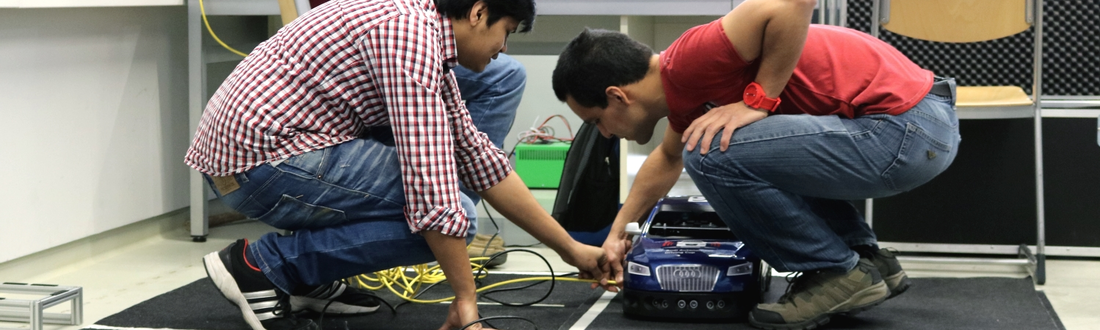

- Model vehicles with learning abilities for autonomous driving

- Control mechanisms for longitudinal and lateral dynamics for self-propelled manoeuvres

Vehicle measurement technology / driving dynamics:

- Four-column lifting platform

- Chassis measuring system / wheel alignment device

- Vehicle dynamics measurement system (longitudinal and lateral dynamics)

- Mobile roller test bench

- Bus measurement technology

- MiL, SiL, HiL test bench

- driving simulator (static) based on CarMaker

- Rapid Prototyping System dSPACE MicroAutoBox

- Simulation Data Management Server

- ADTF - evaluation software

- Vehicle dynamics simulation IPG CarMaker

- Powertrain Simulation AVL Cruise MADYMO - Passenger Movement Simulation

- Basic equipment of software programs like: Catia, Matlab, Ansys, dSpace, etc.

In the laboratory there are sufficient workstations for students. In the winter and summer semester, practical trainings and student projects are regularly carried out for study courses of the Faculty of Electrical Engineering and Computer Science, and also the Faculty of Mechanical Engineering. In these projects, a wide variety of questions from the field of mechatronics are dealt with in the context of vehicle safety, vehicle measurement technology and measurement and data analysis.

Numerous interns and theses, also from international partner universities, are supervised and completed per semester directly in the laboratory and in these subject areas.

Possible courses:

- Introduction to various GPS measurements (single position, code differential position, RTK position, speed, time)

- Getting to know various standard protocols (NMEA, RTCM, ...). Working with raw data from GPS receiver and RTKLIB conceivable

- Fundamentals of structure-borne sound generation and propagation in different materials and their practical application for crash detection

- Fundamentals of crash detection based on

- Structure-borne sound

- Accelerations

- Complex deformation analyses [e.g. iCMS with CFK]

- Predictive sensor technology (cameras, lidar, radar)

- Vehicle communication and GPS - Inertial-based positioning and sensor data fusion

- Vibrations, their suppression by means of viscoelastic absorbers and their application to improve sensor and test systems

- Sensor Technology and Signal Processing

The research activities in the Mechatronics Laboratory (G007) are based on the research programme of the CARISSMA research and test centre. Various working groups are working on the overarching task of contributing to the long-term goal of zero traffic fatalities by means of innovative developments and new approaches. The aim is to further increase both active (accident avoidance) and passive (reduction of accident consequences) safety and to research the interaction of these two aspects in integral safety systems. With the help of the bionic principle, new sensor technologies and networking with other systems will be used to simulate the senses that enable humans to recognise and avert dangers from the environment. In relation to the vehicle, this means feeling accidents (e.g. pressure measurement system PTS, acceleration and rotation rate sensors), hearing (Crash Impact Sound Sensing), seeing (radar, camera) and communicating (WLAN, mobile radio, LTE). This innovative strength was one of the main reasons why the Science Council approved the construction of the CARISSMA (Center of Automotive Research on Integrated Safety Systems and Measurement Area) research and test center on July 2, 2010.

Laboratory management and team

Prof. Dr.-Ing. Thomas Brandmeier

Phone: +49 841 9348-3840

Room: H023

E-Mail: Thomas.Brandmeier@thi.de

Prof. Dr.-Ing. Michael Botsch

Phone: +49 841 9348-2721

Room: K209

E-Mail: Michael.Botsch@thi.de

Prof. Dr. rer. nat. Armin Arnold

Phone: +49 841 9348-7980

Room: B204

E-Mail: Armin.Arnold@thi.de

Dipl.-Ing. Duy Giap Tran

Phone: +49 841 9348-6150

Room: H120

E-Mail: DuyGiap.Tran@carissma.eu

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)