The battery laboratory serves to research and test energy storage systems for hybrid and electric vehicles with regard to their suitability in safety-critical driving situations and for use in vehicle safety.

Objectives and Ideas

The battery laboratories serve research in the field of safe energy storage. In addition to the common battery technologies (especially lithium-ion) and capacitors, the vehicle is also considered as an overall concept. From the point of view of the rapidly advancing electrification, all operating phases of the energy storage systems must be taken into account. This includes the production and use as well as the end of the life cycle and recycling of batteries.

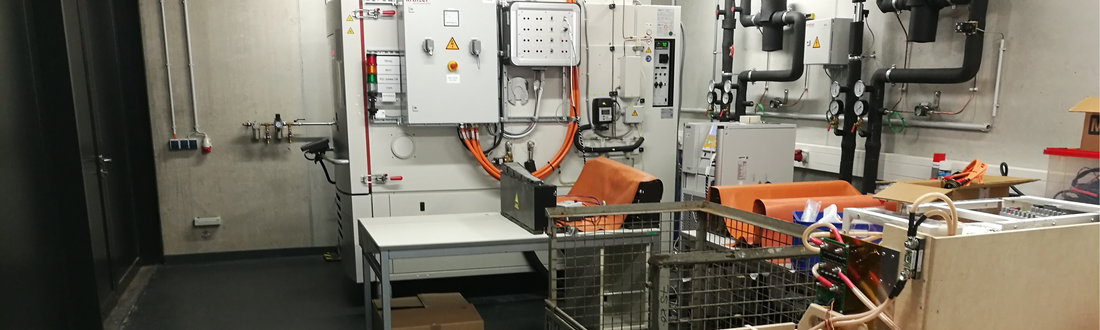

In the battery laboratories, facilities are available for testing individual battery cells (cell tester - 5 Volt, 800 A), battery modules (high-current test bench - up to 60 V, 4000 A, 240 kW) up to large high-voltage battery systems (high-voltage test bench - up to 800 V, 500 A, 150 kW). In addition, numerous temperature and climate chambers are available to ensure that research on energy storage systems can be carried out safely and under constantly reproducible conditions.

Equipment

- 50 to 800 V, 500 A, 150 kW battery test bench / battery simulator with 1.5 m3 temperature chamber for energy storage systems and safety technology for lithium-ion batteries

- 80 V, 4x1000 A, 240 kW battery test bench for high-current tests of battery components and 12 V, 24 V and 48 V on-board battery

- Bitrode cell tester (8 channels; +-100 A per channel; 0 ... 5 V)

- Neware cell tester (140 channels; +-6 A per channel; 0 ... 5 V)

- Energy storage systems can be coupled with temperature/climate chambers from the cell and electromechanics laboratory

- 2x240 l Vötsch temperature chamber with safety technology for lithium-ion batteries

- 240 l ATT climate chamber and Huber cryostat

- 4x160 l Memmert drying ovens

- Digestorium for abuse tests on electromechanical components of battery systems and for cell opening

- 2 electronic workstations equipped with measuring technology (oscilloscopes, multimeters, CAN interface, soldering stations, hand tools etc.)

- Development tools for various microcontrollers (Infineon, Atmel, STM, ...)

- Software for board layout and circuit simulation

- Assembly workstation for HV battery systems including tools and protective equipment for live working

- Hioki milliohmmeter and Schleich insulation testers

- Resistance welding machine for battery cells Miyachi ISQ20-6K

Examples of use

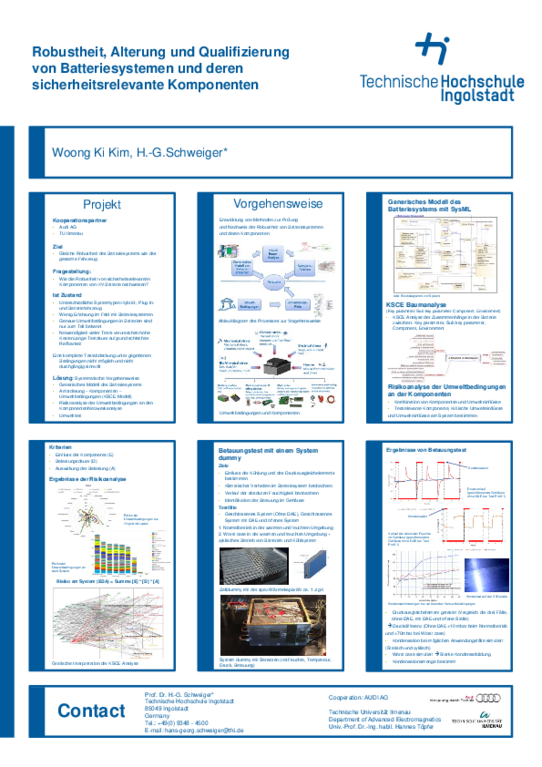

- Research into sources of danger from the interaction of the subsystems

- Research on the impact of battery faults on HEV/EV vehicle safety and dynamics

- Research into the interaction of individual systems in safety-critical driving situations

- Research into the robustness of safety-relevant components and subsystems

- Research into the robust energy supply of safety-relevant vehicle systems

Lab management

Prof. Dr. rer. nat. Hans-Georg Schweiger

Phone: +49 841 9348-4500

Room: H026

E-Mail: Hans-Georg.Schweiger@thi.de

Team

Dipl.-Ing. (FH) Walter Straßer

Phone: +49 841 9348-6872

Room: H025

E-Mail: Walter.Strasser@carissma.eu

![[Translate to English:] ©THI [Translate to English:] Elektronikarbeitsplätze](/fileadmin/_processed_/b/3/csm_Elektronikarbeitsplaetze_a7ff763ba7.webp)

![[Translate to English:] ©THI [Translate to English:] Hochvoltprüfstand Bedieneinheit](/fileadmin/_processed_/0/f/csm_Hochvoltpruefstand_Bedieneinheit_12ff4c66f2.webp)

![[Translate to English:] ©THI [Translate to English:] Zelllabor](/fileadmin/_processed_/6/3/csm_Zelllabor_2b305fa7e8.webp)

![[Translate to English:] ©THI [Translate to English:] Plug-In-Hybird Versuchsfahrzeug](/fileadmin/_processed_/2/2/csm_Plug-in-Hybrid_Versuchsfahrzeug_7857ea4341.webp)

![[Translate to English:] ©THI [Translate to English:] Batteriestack für E-Falke](/fileadmin/_processed_/e/c/csm_THI-Batteriestack_fuer_E-Falke_2d0bee9f14.webp)

![[Translate to English:] ©THI [Translate to English:] Batterieprüfraum](/fileadmin/_processed_/4/7/csm_Batteriepruefraum_neu_79503c95e8.webp)

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)