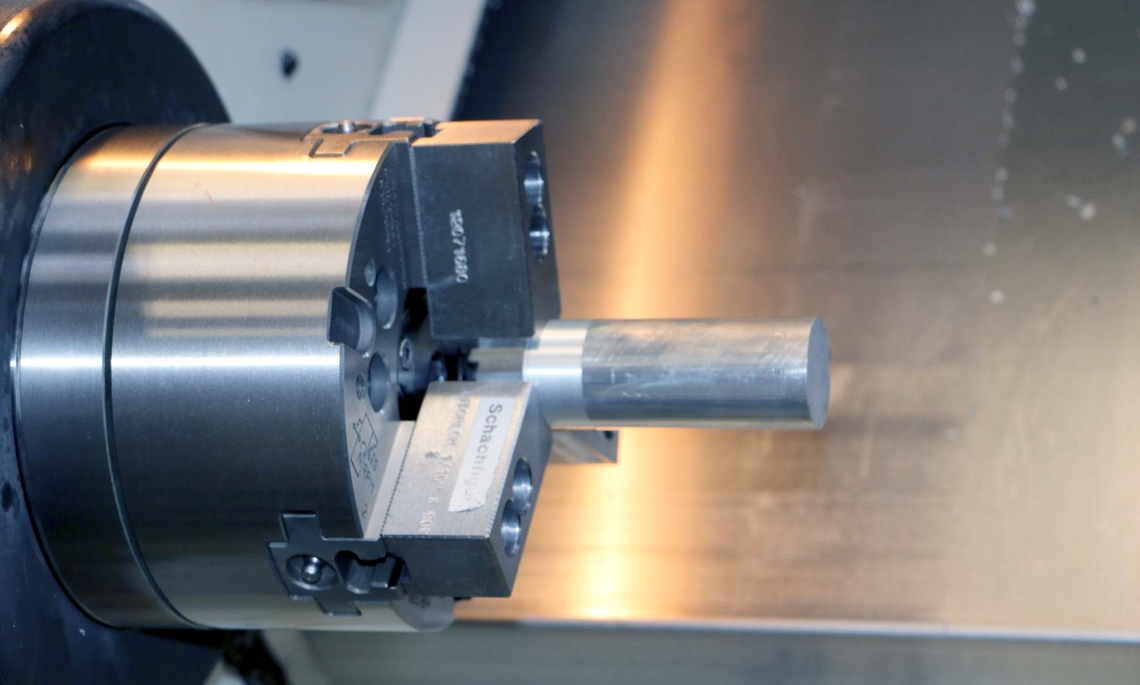

The Production Engineering Laboratory supports the teaching of students in the Faculty of Engineering and Management. Exercises are carried out, e.g. on process optimisation, workplace design and time measurement as well as robotics and interactive worker guidance in assembly. In addition, a virtual planning system is available to virtually set up and test workshops, assembly processes and plants. In addition, milled and turned parts for university use are produced in the laboratory for production technology.

Goals and Tasks

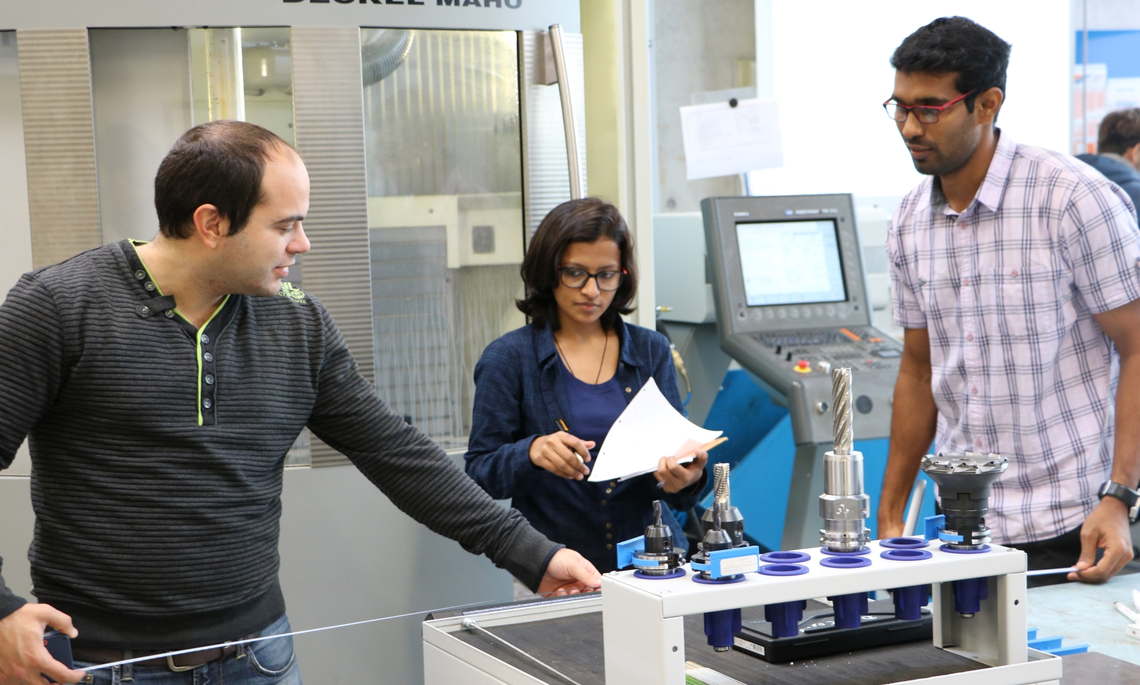

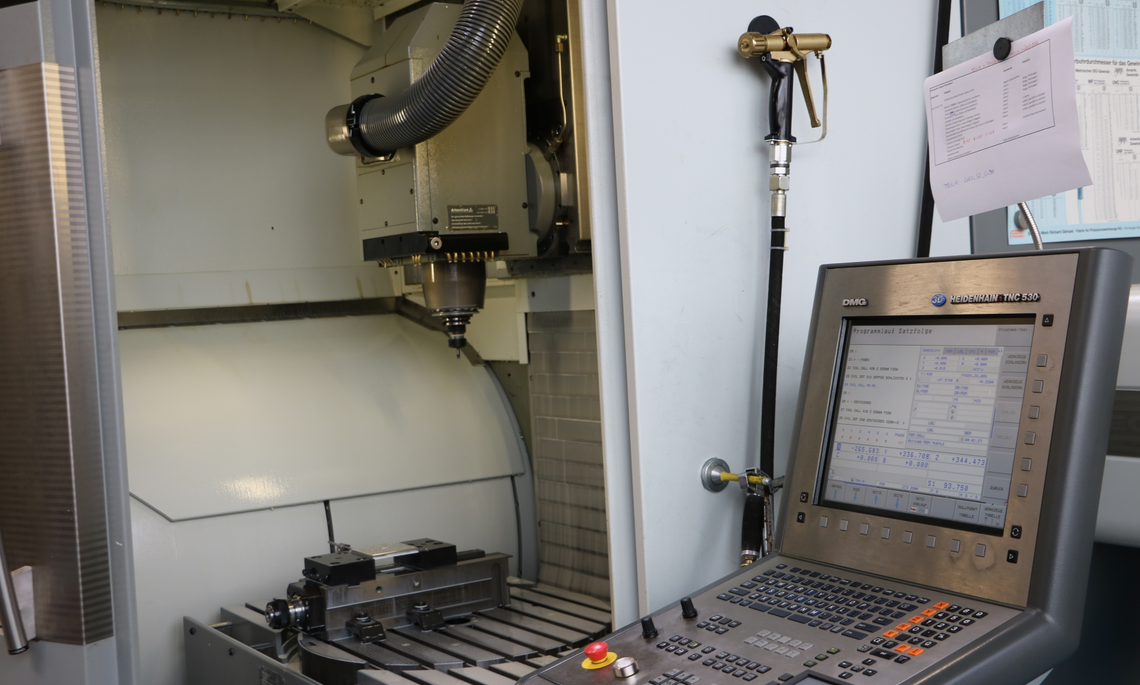

- Training of students in machine tools, CAD/CAM and workshop-oriented NC programming

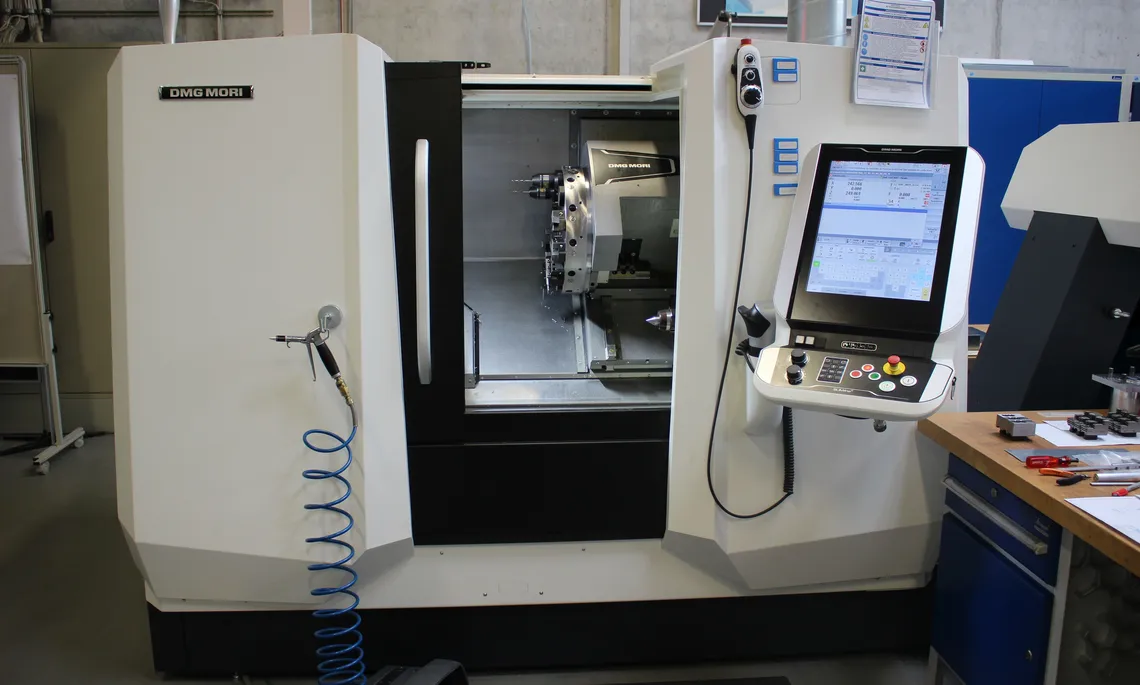

- Practical demonstration of CNC milling machine and lathe

- Teaching optimisation measures and ergonomics at the assembly workplace as well as optimisation of machining processes

- Carrying out time determination in work processes (REFA)

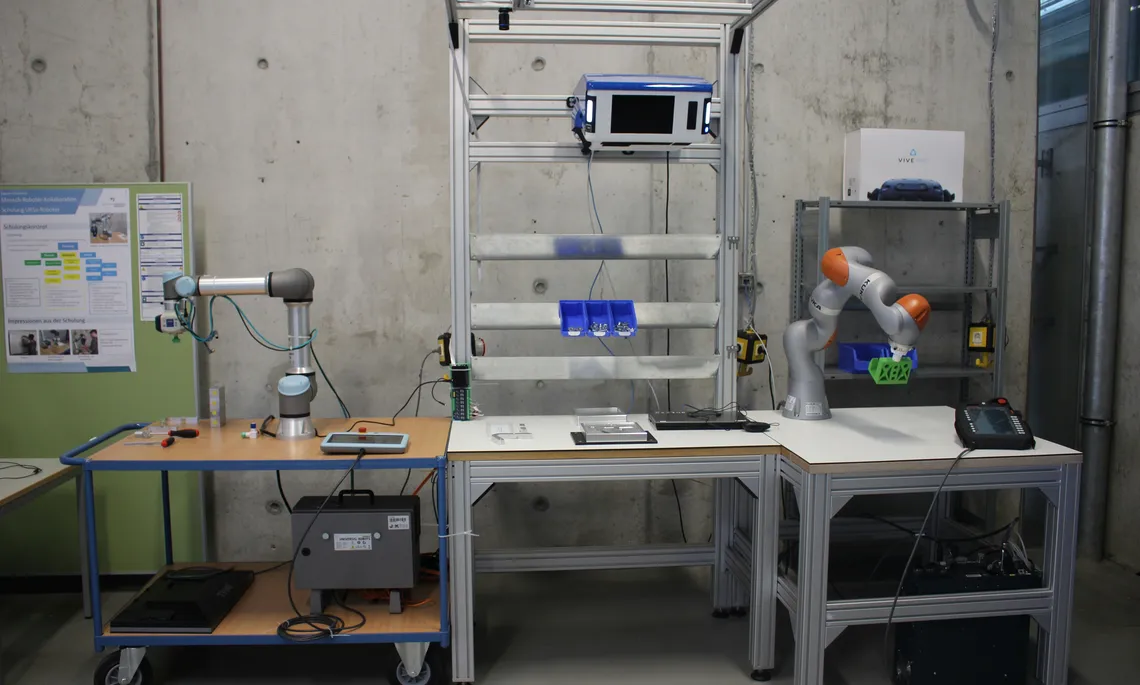

- Programming collaborative robots

- Training for efficient production

Laboratory Equipment and Software

Maschines and Equipment

- CNC 5-axis milling machine DMG 60 monoBLOCK

- CNC Lathe DMGMori_CLX350

- Tool setting device EzSet 400

- Coordinate measuring machine Zeiss Eclipse

- Simulation software Vericut

- VR planning software "Halocline" with VR glasses

- Collaborative robots UR5e and Kuka iiwa

- Assembly assistance and guidance system from Ulixes (the assistant)

Courses

- Machine tool demonstration

- Exercise workplace analysis / MTM (value creation, ergonomics, cycle time, video analysis)

- Exercise measuring equipment capability

- Exercise process optimisation

- Exercise quick set-up (SMED)

- Exercise production training

- Exercise Value stream

- Practical seminar "Production optimisation

- Optional subject "CAD/CAM for 3D printing, machining and robotics

Laboratory management and team

Vice Dean Faculty of Engineering and Management

Prof. Dr. Martin Bednarz

Phone: +49 841 9348-3508

Room: A221

E-Mail: Martin.Bednarz@thi.de

Prof. Dr. Martin Bednarz

Phone: +49 841 9348-3508

Room: A221

E-Mail: Martin.Bednarz@thi.de

![[Translate to English:] Screenshot Startbildschirm 360-Grad-Rundgang](/fileadmin/_processed_/e/c/csm_C023_Screenshot_360GradRundgang_1186295f30.webp)

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)