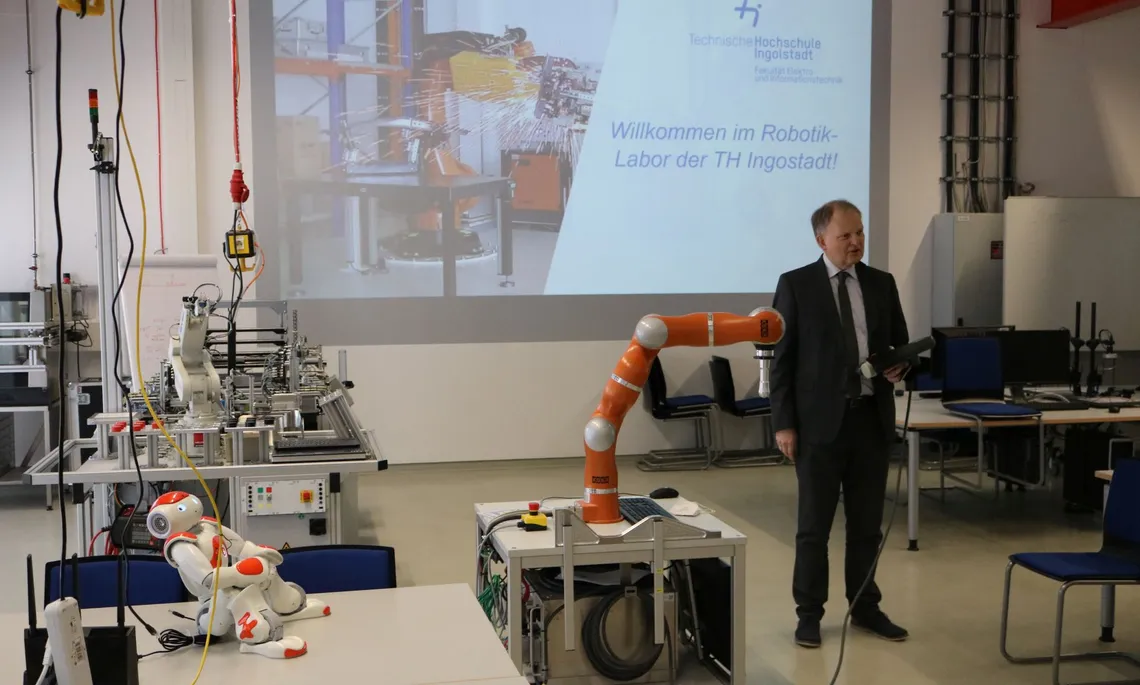

The robotics laboratory is a central facility for exercises, internships, projects and final theses for production-related degree programmes at the TH Ingolstadt. It can also be used for experimental investigations as part of research projects. The laboratory focuses on robotics, automation technology and industrial image processing. The laboratory is also used for transfer activities.

Goals and idea

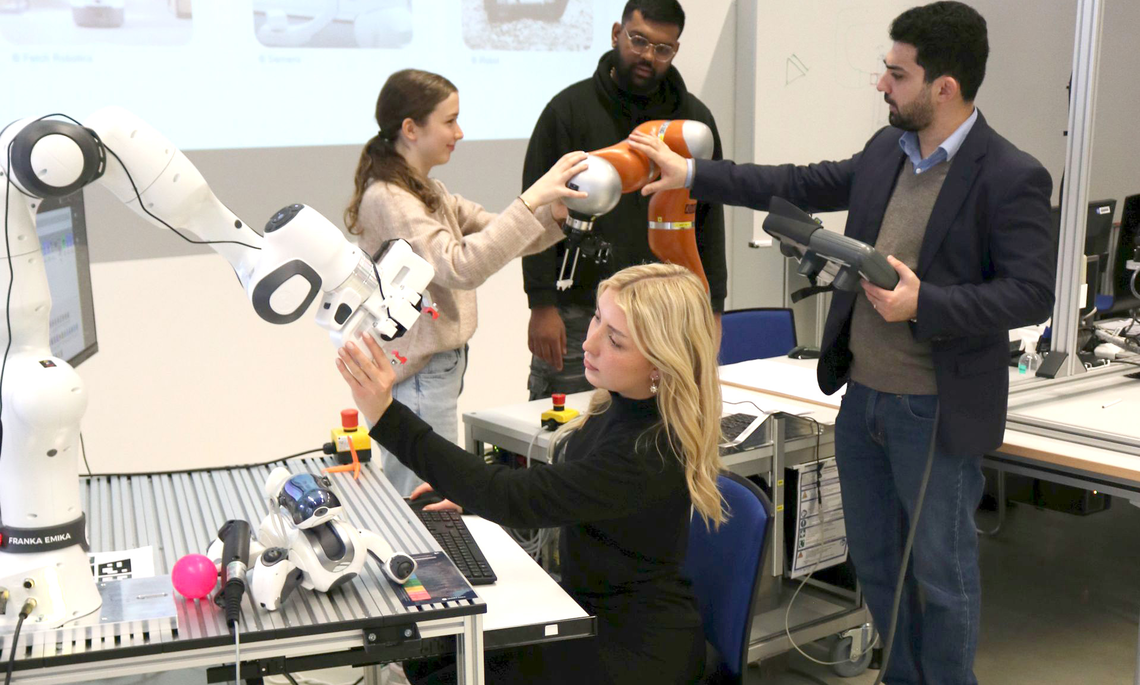

The robotics laboratory has an area of approx. 200 m². It houses a robot cell with two KUKA co-operating industrial robots with high payloads: these are intended for welding and joining applications as well as handling tasks. The laboratory is also equipped with various HRC-capable robots (also known as cobots). Robot applications and cooperation with humans can be realised using the existing sensor technology, robot tools and AI methods. Various mobile robot platforms and service robots are also in use.

Laboratory equipment and activities

The Robotics Lab has various types of robots:

- Franka Emika Research robots

- Two classic KUKA KR 240 industrial robots (in the form of the double robot system) equipped with a welding system

- Universal Robot UR5

- one position- and force-controlled lightweight robot KUKA LBR4+

- Mitsubishi industrial robots

- several mobile robot platforms TurtleBot3

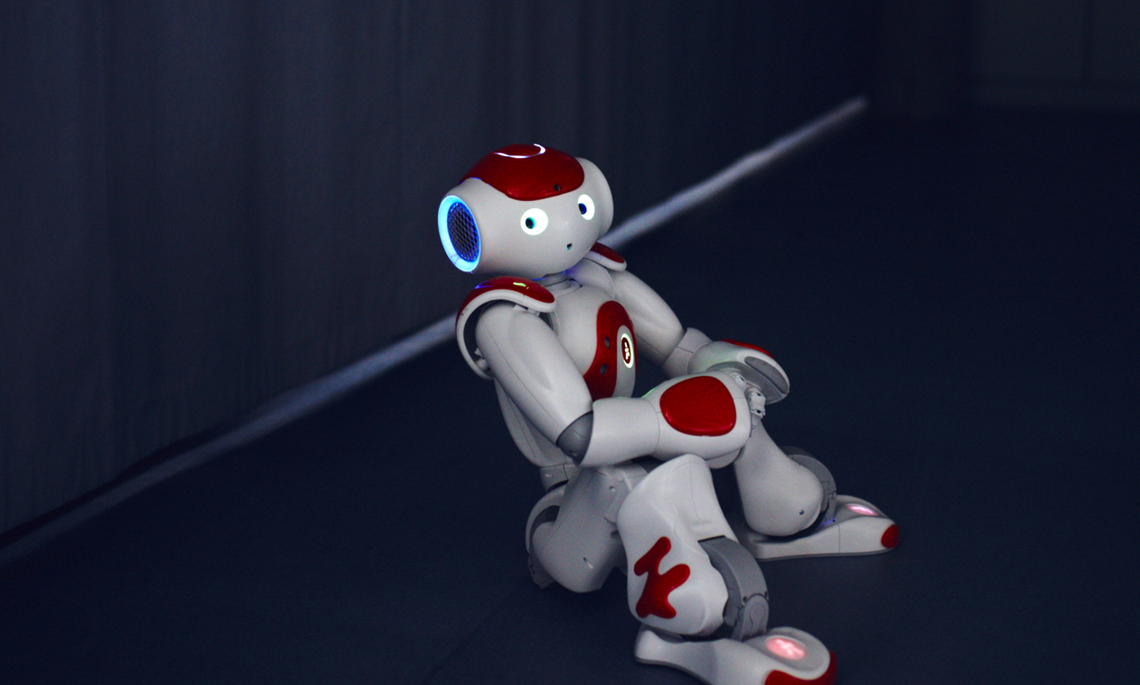

- one humanoid robot NAO

- four Sony AIBO dog robots

- two modern 3D cameras (OAK-D) with integrated processor for AI applications

- various grippers

With these robots we realize on the one hand classical joining and assembly tasks from industrial production, but on the other hand also novel applications, where the cooperation of several robots as well as the cooperation with humans are in the focus. For the latter applications, sensor technology is of great importance; only a large number of sensors (cameras, force sensors, tactile sensors) enable robots to act and react "intelligently" in changing situations.

Besides the robots themselves, the grippers or robot hands are also important. The laboratory is equipped with a three-finger gripper hand from Schunk, whose fingers are equipped with tactile sensors and can therefore sense objects and their shape.

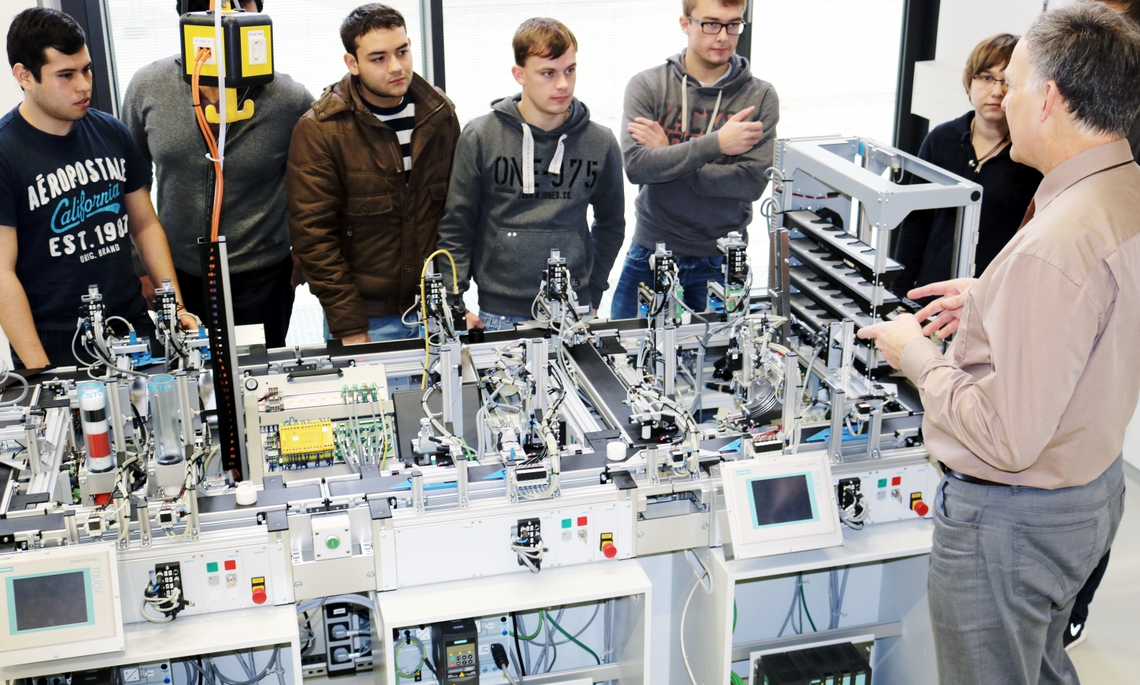

Mechatronic Learning Factory:

For teaching and research in control and automation technology, the laboratory is equipped with a mechatronic learning factory from Festo didactic. This learning factory simulates production tasks by guiding workpieces with RFID tags on conveyor belts to processing stations where real or simulated value creation takes place (e.g. measuring, assembling, drilling, turning, storing, sorting, etc.); a six-axis robot is part of the learning factory. The learning factory has 5 SPS-7s, which control the stations via ProfiBus and ProfiNet. The topology of the learning factory can be changed at any time, so that different configurations of a production line can be simulated. All control tasks including the robot programs can be simulated and visualized with the CIROS software, so that a step-by-step "virtual commissioning" of a new production task is possible.

Laboratory management and team

Prof. Dr.-Ing. Ali Kanso

Phone: +49 841 9348-3818

Room: A105

E-Mail: Ali.Kanso@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)