The Laboratory for Modeling and Model-Based Development Methods is concerned with the creation, implementation and validation of simulation models of electromechanical systems. Taking into account the physical relationships and their mathematical description, real systems can be transformed into models.

Goals and idea

Models can represent the real behaviour with respect to a defined problem with sufficient accuracy. Thus, a large number of experiments can be carried out on the model and their results can be transferred to the real system.

With increasingly powerful IT systems with appropriate software (e.g. Matlab/Simulink), these models can be implemented and subsequently simulated with the desired input variables. Taking into account the limitation that a simulation can never exactly reproduce reality, first insights into the real behaviour can be drawn from the model before a first prototype exists. With the possibility to vary the input variables of the model quickly and easily, essential advantages of model-based methods are obvious.

Furthermore, it will be shown how model-based development methods can support the development and optimization of real technical systems in order to improve the development process in terms of time and cost.

More and more development tasks are price- and especially time-driven. An example of this is the development of a modern vehicle, which takes place in ever shorter development cycles and is intended to serve a large number of different vehicle derivatives. Countless real test vehicles cannot be set up to perform individual parameter optimizations. This would be too costly and would require an unacceptable amount of time. The available methods of model-based development can support test and validation tasks to a high degree or perform them independently and automatically. The deterministic behaviour of the simulations allows a reproducibility of tests that is difficult to represent in reality, which offers great advantages especially in the search for and correction of errors.

- Training of students in the field of modelling and simulation-supported development methodology

- Carrying out practical training experiments:

- Analysis of technical systems with regard to input/output variables and transmission behaviour

- Creation of suitable simulation models in Matlab/Simulink

- Validation of the simulations through real tests

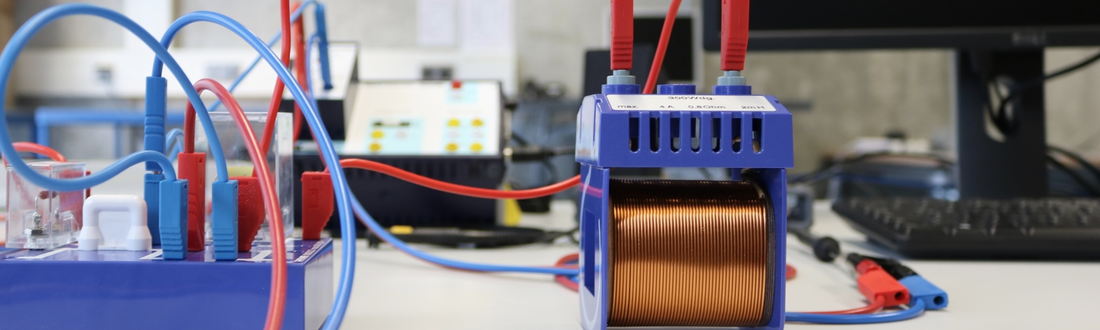

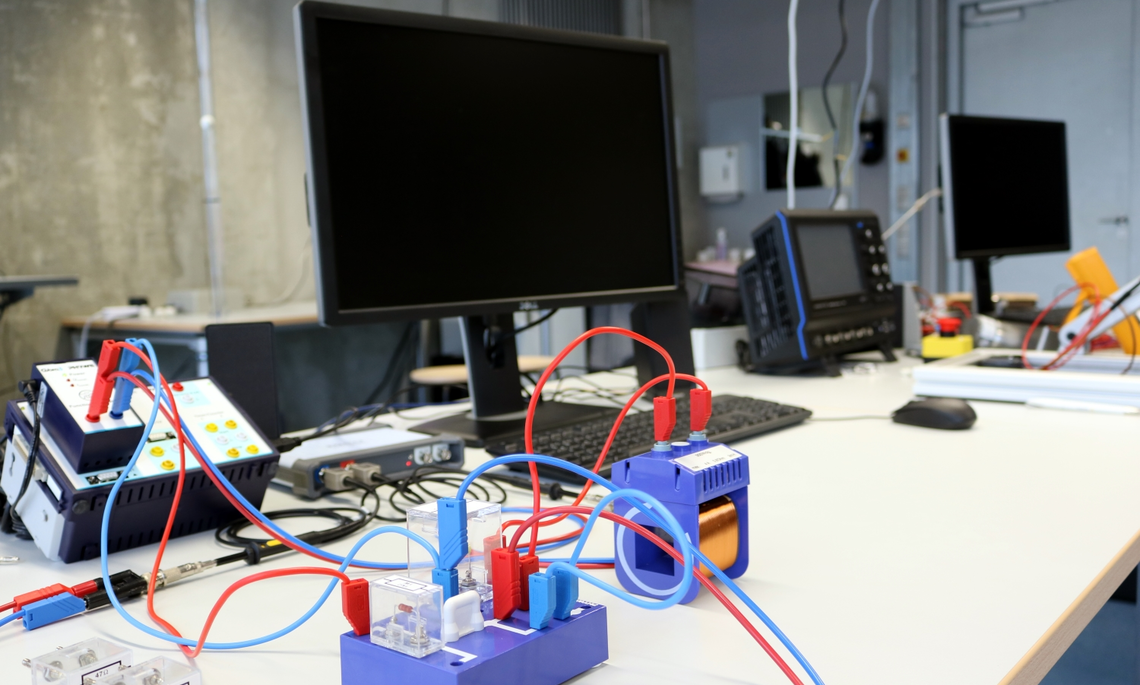

Laboratory equipment and activities

- 4 practical training places:

- Experiment 1: Physical pendulum

- Experiment 2: Electrical oscillating circuit

- Experiment 3: Electromotive lifting of a load

- Experiment 4: Inverted pendulum - 3 further PC workstations

- Measurement technology and electronic equipment

- Oscilloscopes; multi-channel

- various laboratory power supply units for power supply

- Function Generator

- Soldering station

- Programming tool for microprocessors

- Hardware for analysis of the CAN bus

- MathWorks Matlab & Simulink

- Etas INCA

- Vector CANalyzer

- National Instruments LabView and Diadem

- lecture-supporting practical courses:

- Modelling and Simulation of Dynamic Systems

- Modelling of complex systems - Other activities

- Study projects

- Theses

- Industrial Projects

Laboratory management and team

Prof. Dr.-Ing. Thomas Schiele

Phone: +49 841 9348-2870

Room: B101

E-Mail: Thomas.Schiele@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)