Packaging and interconnection technology is a key technology for microelectronics. Miniaturization of electrical systems with simultaneously increasing performance under high cost pressure poses a growing challenge to materials, connection processes, mechanical and electrical contacts (soldering, bonding, sintering) and thermal management. The Internet of Things (IoT) was and is only made possible by innovations in packaging and interconnection technology.

Goals and idea

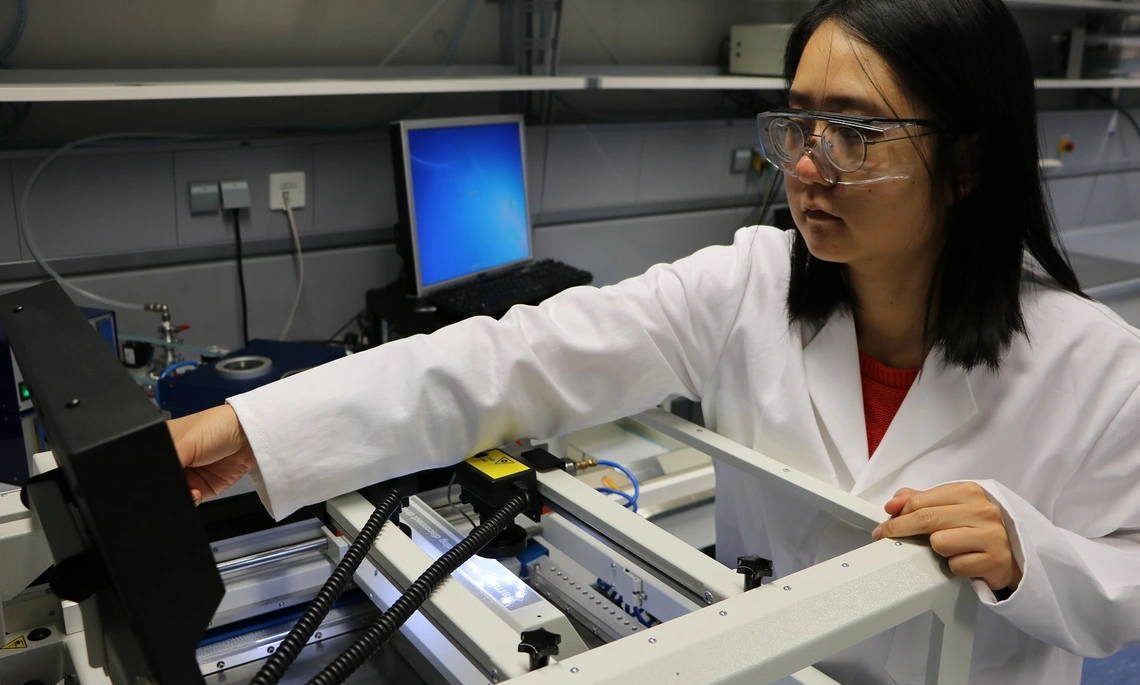

The Internet of Things (IoT) was and is only made possible by innovations in packaging and interconnection technology. Also in the automotive sector at high operating temperatures under strong mechanical and thermo-mechanical stress, the demands on PIT are particularly high. As the density of electronics in the vehicle continues to increase - also in the safety-relevant area - PIT has an outstanding role to play in the reliability and safety of mobility in the 21st century. The Laboratory for Packaging and Interconnection Technology deals with the realization of solder, sinter and adhesive connections in the field of SMD technology. Climate, temperature and shock chambers are used for accelerated aging tests. Cross sections, scanning electron microscopy, pull/shear tests can be carried out for analysis at the university.

Laboratory equipment and activities

- Semi-automatic stencil printer

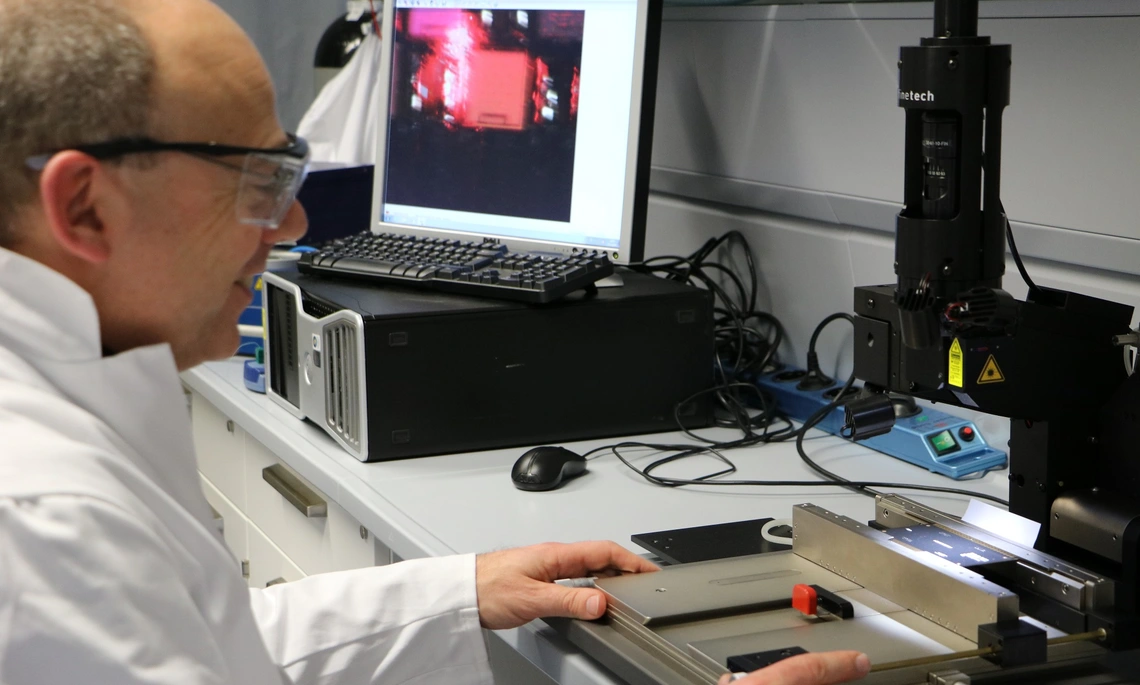

- Die-Placer/Bonder with in-situ process monitoring and substrate heating module (for thermocompression bonding, thermode soldering and sintering)

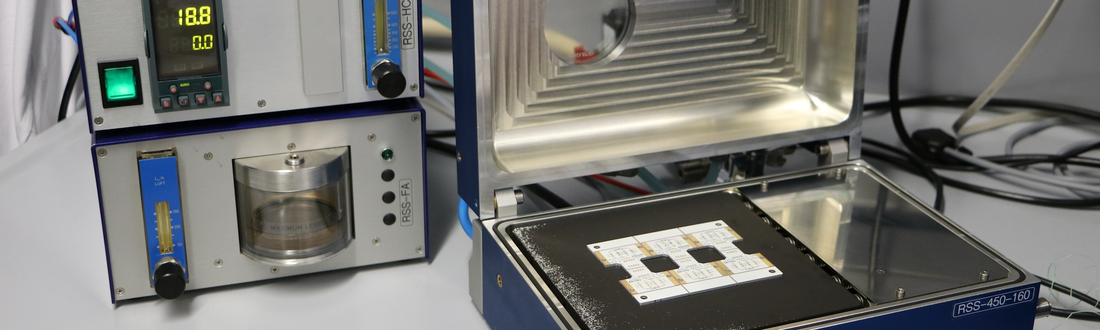

- SMD furnace and vacuum soldering furnace for remelting under vacuum (low porosity soldering) and process gas (flux-free soldering)

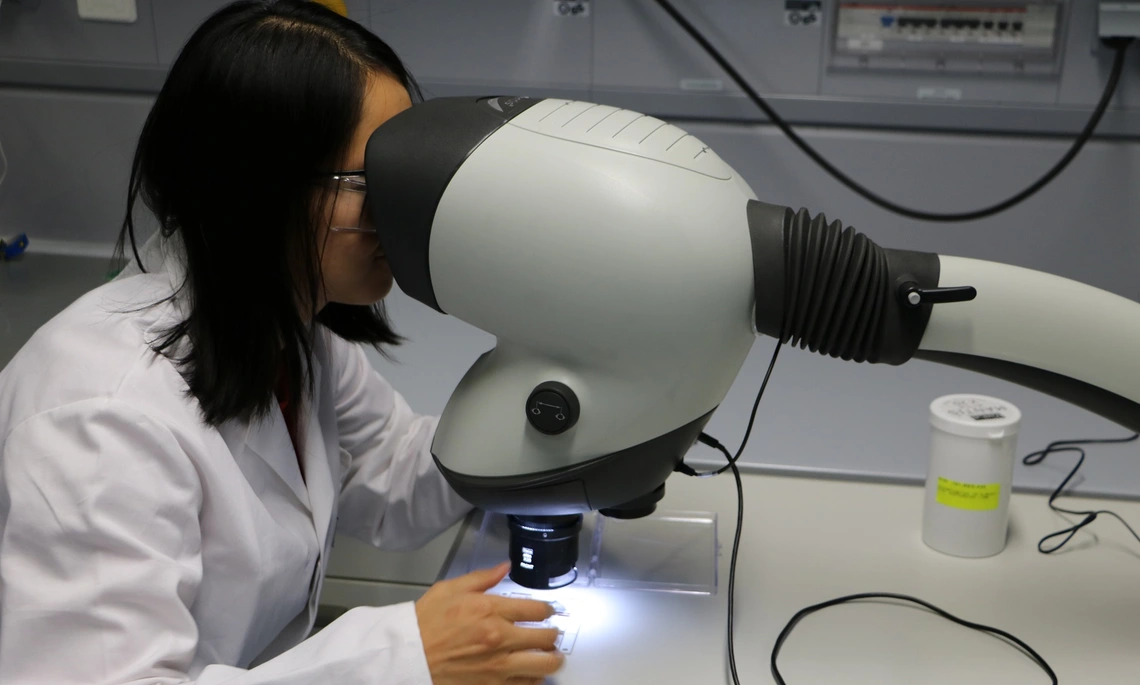

- 3D microscopy for the creation of 3D images for optical inspection 3D microscope with motorized z-axis and tiltable objective

- Temperature shock chamberMTF Measuring stand (modulation transfer function)

- Keyence: 3D software

- Finetech: WinFlipChip software for controlling bond processes

- Solid-Works: for mechanical analyses

- Mentor Graphics EFD-Flow: for thermal design and analysis

Training of students in the field of assembly and connection technology:

- Surface Mount Technology (SMT): solder paste printing, optical inspection, placement of components and reflow

- Connection technologies for semiconductors: flux-free soldering processes, vacuum soldering and sintering

- Connection technology for optoelectronics: Positional accuracy of the assembly and the floating-in behaviour (self-alignment)

- Determination of the resolution power of optical systems

- Connection technology for cable harness: ultrasonic welding of copper cables

- Thermal analysis for inspection of the thermal path

- Reliability analysis via accelerated ageing tests

Internships accompanying the lectures:

- SMD Soldering and Ultrasonic Welding (Packaging and Connection Technology of Microelectronics)

Other activities:

- Laboratory for student projects for manufacturing SMD assemblies

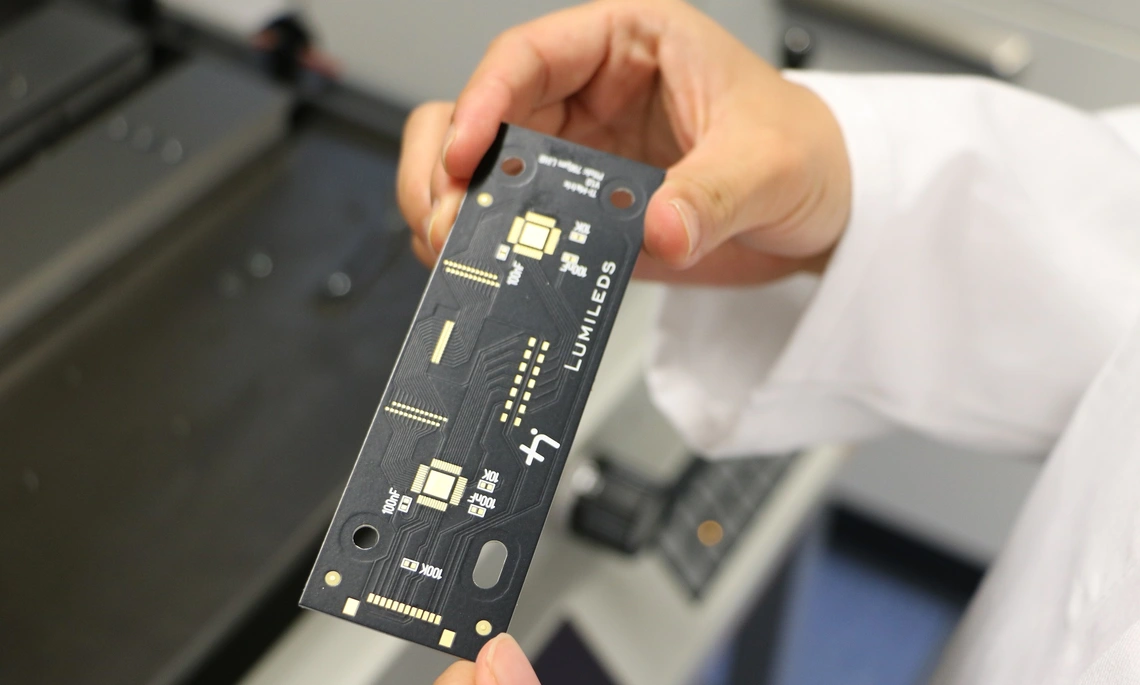

- Study projects: LED Lamp THI, Miniaturized Microelectronics

- Theses (Bachelor & Master)

- Industrial projects

- SmartLED: Development of a flux-free solder paste process for LED modules, measurement method development for reliability and lifetime predictions of LED modules, analysis of driver architectures; Industrial partners: Lumileds, Heraeus

- ZuKo: process development for electrical and mechanical contacting of power electronics components (soldering and sintering) and electrical connections (welding), development of non-destructive measurement technology for the analysis of contact quality and reliability; industrial partners: OSRAM, BMW

- Visi0n: Failure analysis of manufacturing processes, failure analysis and test method development for complex electronic modules (driver assistance systems); Industrial partners: Continental, Anylink Alexander: LED

Lab Management and Team

Prof. Dr. Gordon Elger

Phone: +49 841 9348-2840

Room: A114

E-Mail: Gordon.Elger@thi.de

Dipl. Ing. (FH) Kirsten Windhorn

Phone: +49 841 9348-2844

Room: C307

E-Mail: Kirsten.Windhorn@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)