The Manufacturing Technologies Laboratory includes additive manufacturing (3D printing) - an emerging and innovative manufacturing process that is fundamentally different from conventional manufacturing processes and thus offers completely new possibilities - and sheet metal manufacturing. Both processes are mapped from design to the finished component.

Goals and idea

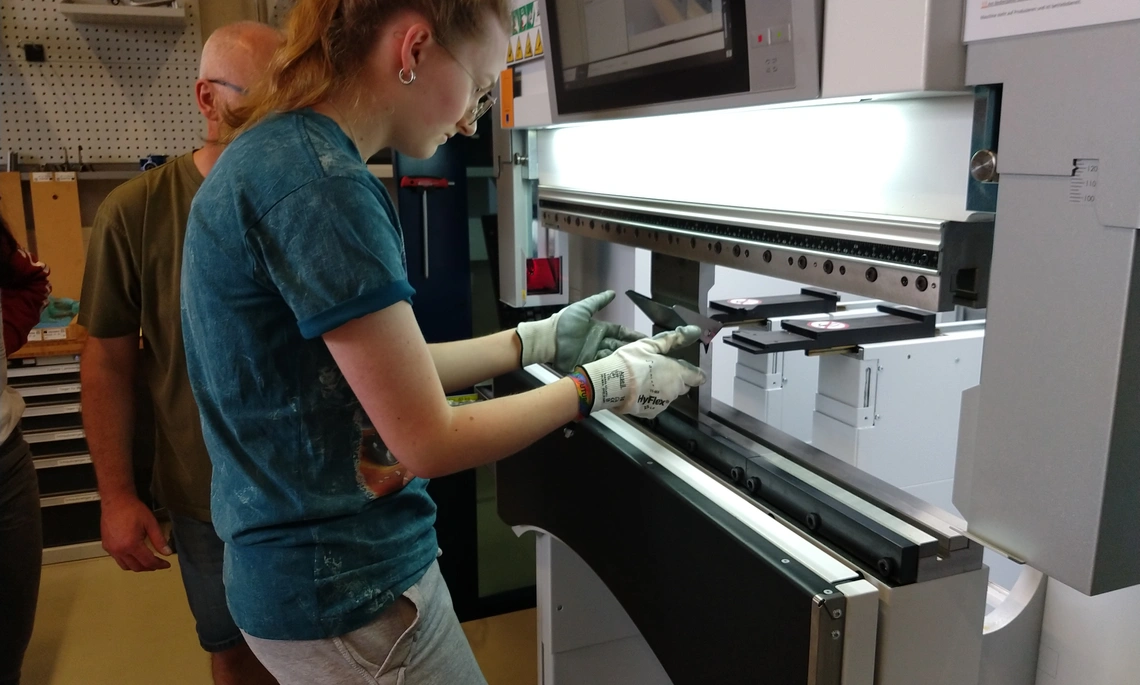

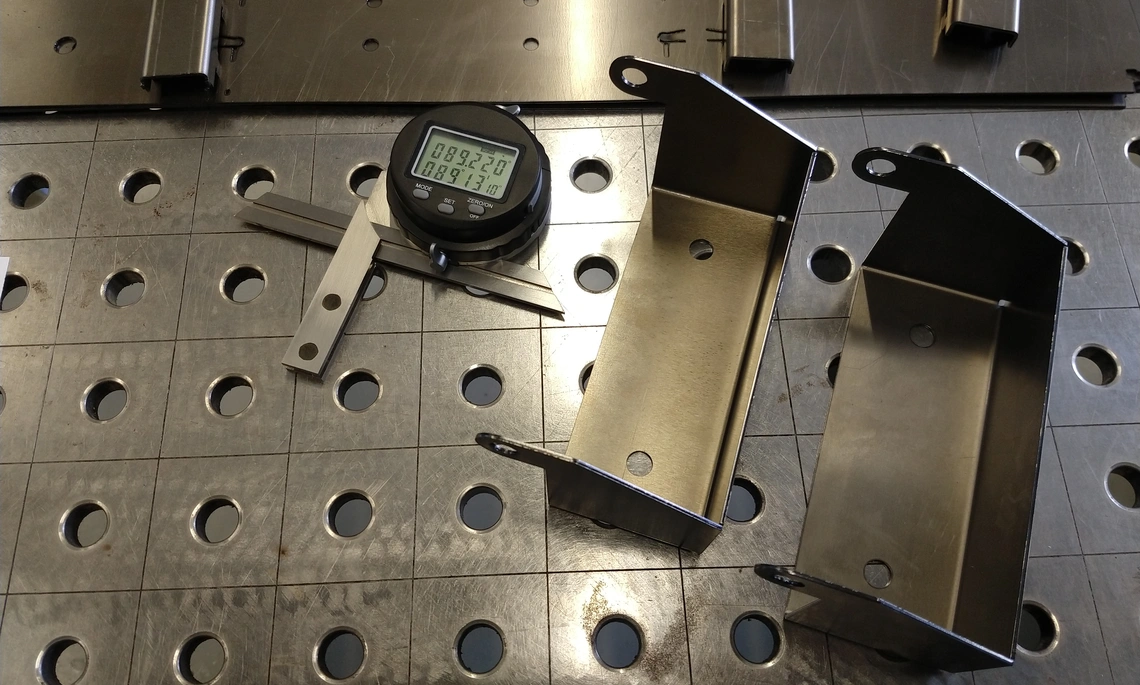

Presentation of the process chain "sheet metal" for medium-sized mechanical engineering companies (CAD design, laser cutting, bending); utilization of the process chain in lectures and projects

Representation of generative manufacturing possibilities (3D printing metal and plastic)

Illustration of manufacturing possibilities for hybrid constructions by suitable joining methods (clinching).

Additive manufacturing

Several FDM or FFF printers (Fused Deposition Modeling or Fused Filament Fabrication) are operated for additive manufacturing. The basic principle is very similar for all these printers:

- A plastic wire (called filament) is fed to the printer.

- The filament is melted.

- The melt is built up layer by layer and a 3-dimensional model of a component is created.

The design freedom here is very large and CAD data can be played directly to the 3D printer with a short processing. Nevertheless, manufacturing restrictions must also be taken into account here. A wide range of printers can process different materials and different resolutions. One of the printers can also process a reinforcing material, both in the form of short fibers and continuous fibers.

Another printer implements an inkjet technology. It can realize very fine resolutions (layer thickness 20 µm, 635 x 400 dpi) and achieves a high printing speed by parallel discharge of the printed material from 256 nozzles. An other technology shown is low force stereolithography. The corresponding printer applies a resin that is cured by laser exposure. The layer thickness is variable (25 µm - 300 µm) and the resolution is 25 µm.

3D Printing Center

Additive manufacturing is used intensively for student projects. In connection with the establishment of additive manufacturing, a 3D printing center was therefore set up. Via the Moodle teaching and learning platform, students can file print jobs that are subsequently executed on the printers. Likewise, practical workshops for 3D printing can be booked and detailed information on the printers can be viewed via this platform.

Sheet metal components

Sheet metal components are used in a wide variety of ways in mechanical engineering, from simple sheet metal angles to elaborate machine frames, from cladding parts, doors and flaps to sophisticated functional components. The advantage of sheet metal fabrication is that only a few semi-finished products, namely sheet metal, need to be kept in stock, from which elaborate components can be manufactured in a very fast production process. Sheet metal structures can often be used to replace milled parts, cast or injection-molded components, or even welded structures made from cut-to-length profiles, thus considerably reducing manufacturing costs. The aim of such an approach is always to make optimum use of the manufacturing possibilities in order to develop components with the same functionality but often with a different appearance.

Laboratory management and team

Prof. Dr.-Ing. Klaus-Uwe Moll

Phone: +49 841 9348-2750

Room: A122

E-Mail: Klaus-Uwe.Moll@thi.de

Prof. Dr.-Ing. Harald Göllinger

Phone: +49 841 9348-3780

Room: A208

E-Mail: Harald.Goellinger@thi.de

Prof. Dr.-Ing. Ulrich Tetzlaff

Phone: +49 841 9348-3520

Room: A232

E-Mail: Ulrich.Tetzlaff@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)