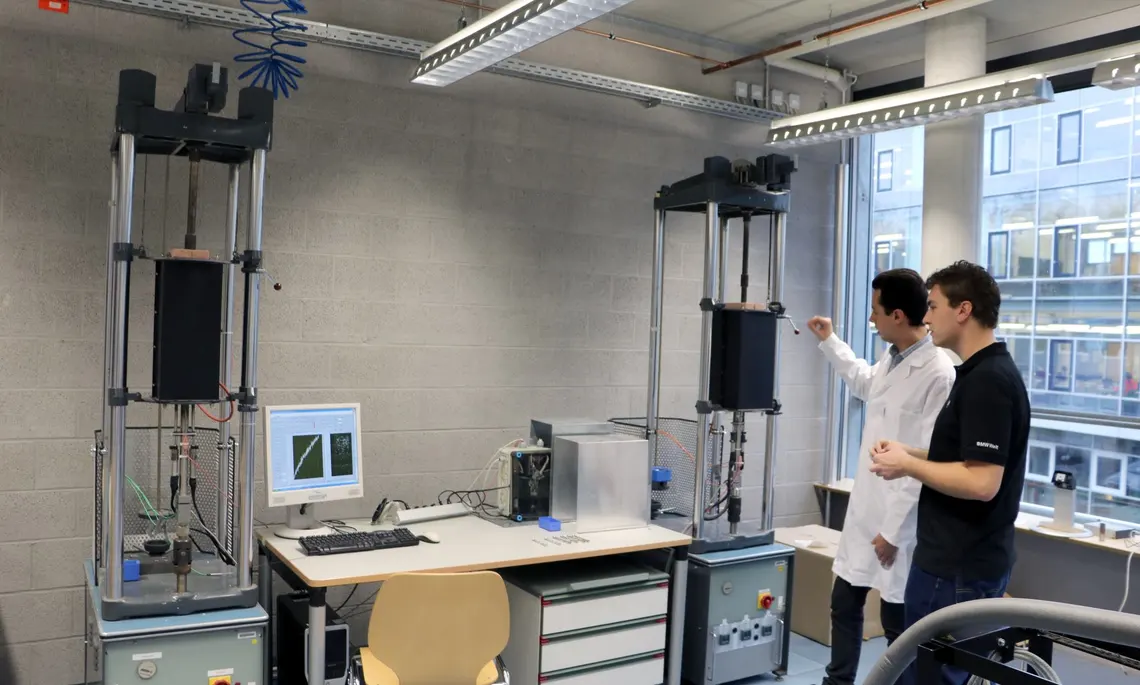

The Laboratory for Materials Analysis is basically concerned with the investigation of the effect of microstructure on the mechanical behaviour of materials. The aim is to scientifically analyse current issues, especially in automotive and aerospace engineering, and to derive new concepts for the future. The laboratory is integrated into the Center for Applied Research (ZAF), which combines all research activities of the competence field of materials and surface technology.

Goals and idea

The application-oriented research projects are mainly carried out in cooperation with medium-sized industrial partners as well as with research institutions and partner universities.

- Fatigue and creep behaviour of metallic materials

- Fatigue and creep behaviour of composite materials

- Tribological studies

- Material analysis e.g. by means of XRD

Laboratory equipment and activities

Equipment and function

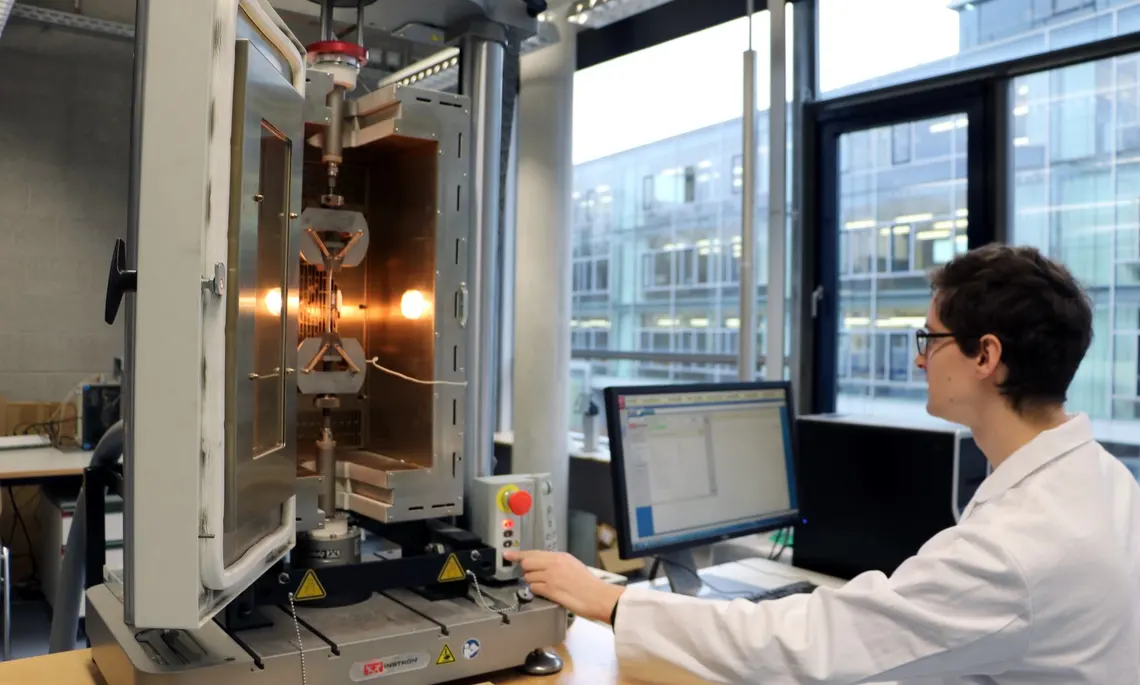

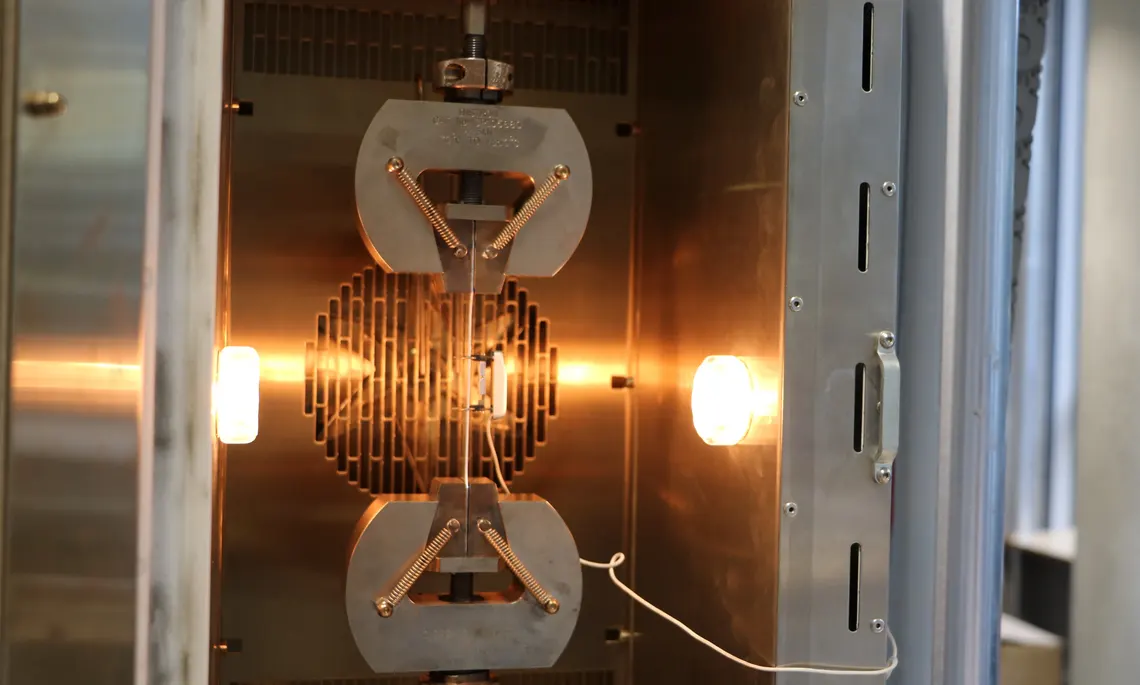

- 2 tensile creep doors for temperatures up to 1100°C and loads up to 20 kN

- 4 tensile creep doors for temperatures up to 250°C (under construction)

- 1 Electrodynamic fatigue machine for temperatures up to 350°C and loads up to ± 3 kN

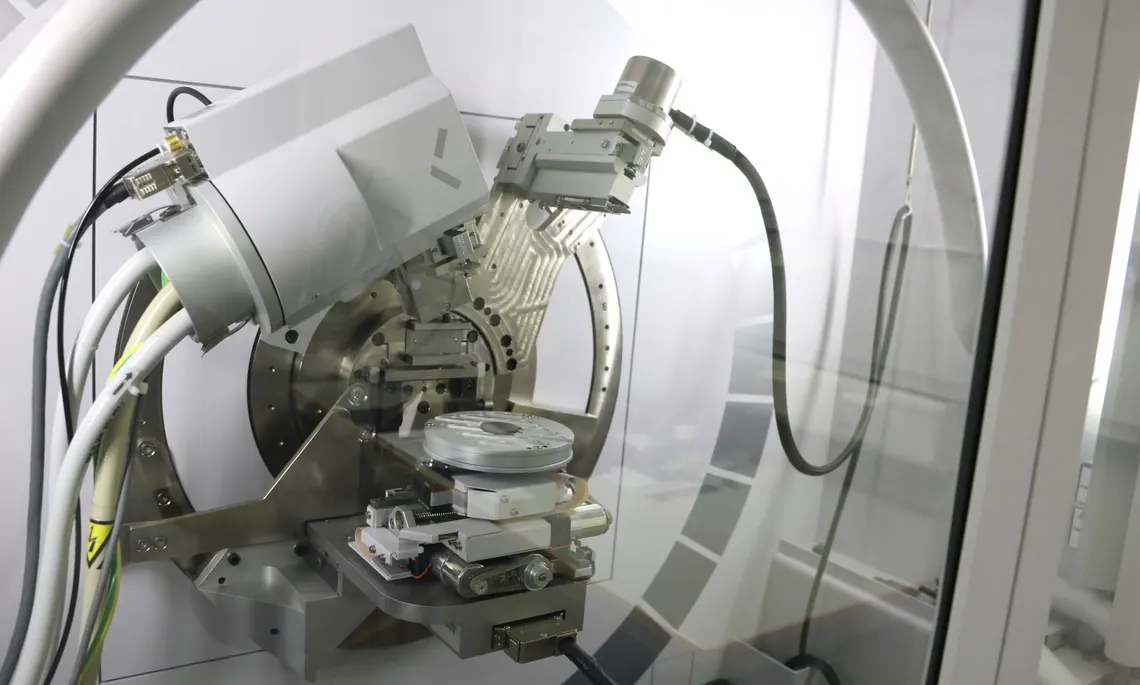

- X-ray diffractometer (XRD) with Bragg-Brentano, lens and parabolic mirror optics

- Software for qualitative and quantitative phase analysis from XRD data

- Software for determining residual stresses from XRD data

- Thermomechanical universal testing machine (in planning)

The materials analysis laboratory is closely related to the materials engineering laboratory.

Courses

Practical trainings accompanying the lectures

- Materials Engineering

- Materials Engineering II

- Material Analysis

- Long-term behaviour of the materials

- Fatigue strength and fracture mechanics (planned)

Research

- Creep and fatigue behaviour of solder materials

- Creep and fatigue behaviour of metallic composite materials (MMC)

- Tribological behaviour of sliding pairings

- Metallurgy of welded joints

Laboratory management and team

Programme director and Academic advisor Material Science in Engineering (Master)

Prof. Dr.-Ing. Ulrich Tetzlaff

Phone: +49 841 9348-3520

Room: A232

E-Mail: Ulrich.Tetzlaff@thi.de

Prof. Dr.-Ing. Ulrich Tetzlaff

Phone: +49 841 9348-3520

Room: A232

E-Mail: Ulrich.Tetzlaff@thi.de

Prof. Dr. mont. Annegret Kerschenlohr

Phone: +49 841 9348-1750

Room: A121

E-Mail: Annegret.Kerschenlohr@thi.de

Phone: +49 841 9348-1750

Room: A121

E-Mail: Annegret.Kerschenlohr@thi.de

Deputy Women's Representative, Programme director and Academic advisor Automotive Engineering

Prof. Dr.-Ing. Manuela Waltz

Phone: +49 841 9348-3530

Room: A232

E-Mail: Manuela.Waltz@thi.de

Prof. Dr.-Ing. Manuela Waltz

Phone: +49 841 9348-3530

Room: A232

E-Mail: Manuela.Waltz@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)