With our experimental stations on fluid mechanics, aero- and thermodynamics and energy technology, the laboratory touches on numerous engineering fields in aviation and automotive engineering, but also in (racing) sports or even surfing! A further focus of research and teaching is in the field of renewable energies.

Laboratory equipment and activities

- Flow optimization

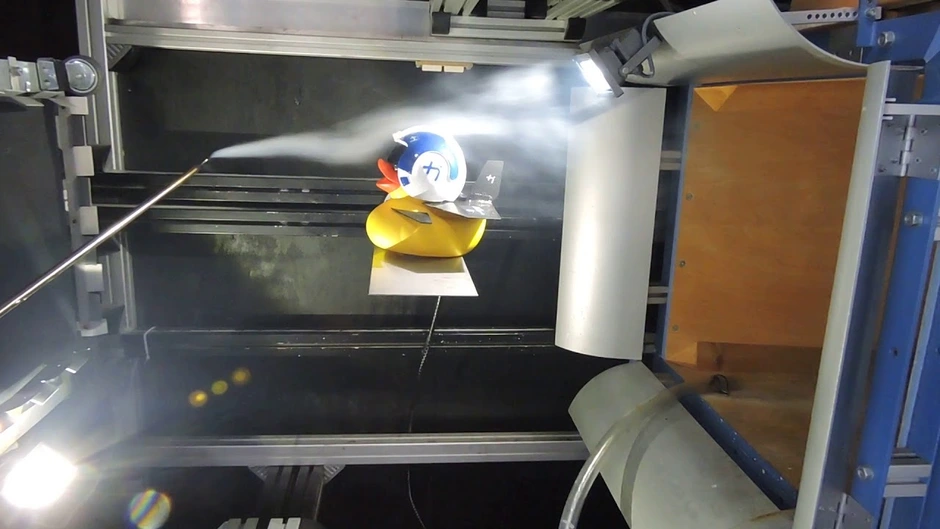

- Wind tunnel measurements (measurement of forces and moments, velocity measurement with hot-wire anemometry and PIV, pressure measurements, flow visualization, ...)

- Surf wave on rivers

Munich raft site

Munich Eisbach

Ingolstadt Danube surf wave

- Flow simulations

Vehicles in original scale and model scale

Motorsports

Aircraft airflow

Surf waves

Refuelling

Compressed air nozzles (transonic)

and much more ...

- Formula Student Electric (Schanzer Racing Team)

Cooling

Aerodynamics

Curving ("cornering")

- Eco Shell Marathon: Aerodynamics (optimization)

- Vehicle aerodynamics (fluid mechanics)

Vehicle air conditioning

Refuelling simulations

Crosswind influence

Column tour

- High performance sports (aerodynamics)

Ski Jumping

Bob of 2

Riblets effect on ski sole

The laboratory has, among other things, the following laboratory equipment (the essential characteristics are given in brackets).

Test benches:

- Wind tunnel (Hyperschall-&Strömungstechnik GmbH, HAST, Göttinger design; nozzle 500mm x 600mm; contraction 6.5:1; length of measuring section 1300mm; vmax=48m/s=173km/h; power 18.5kW)

- Audi model wind tunnel (Göttinger design; 1:20 model of the aeroacoustic wind tunnel of Audi-AG; nozzle 140mm x 197mm; contraction 5.5:1; length of measuring section 300mm; vmax=45m/s=163km/h; power 3kW)

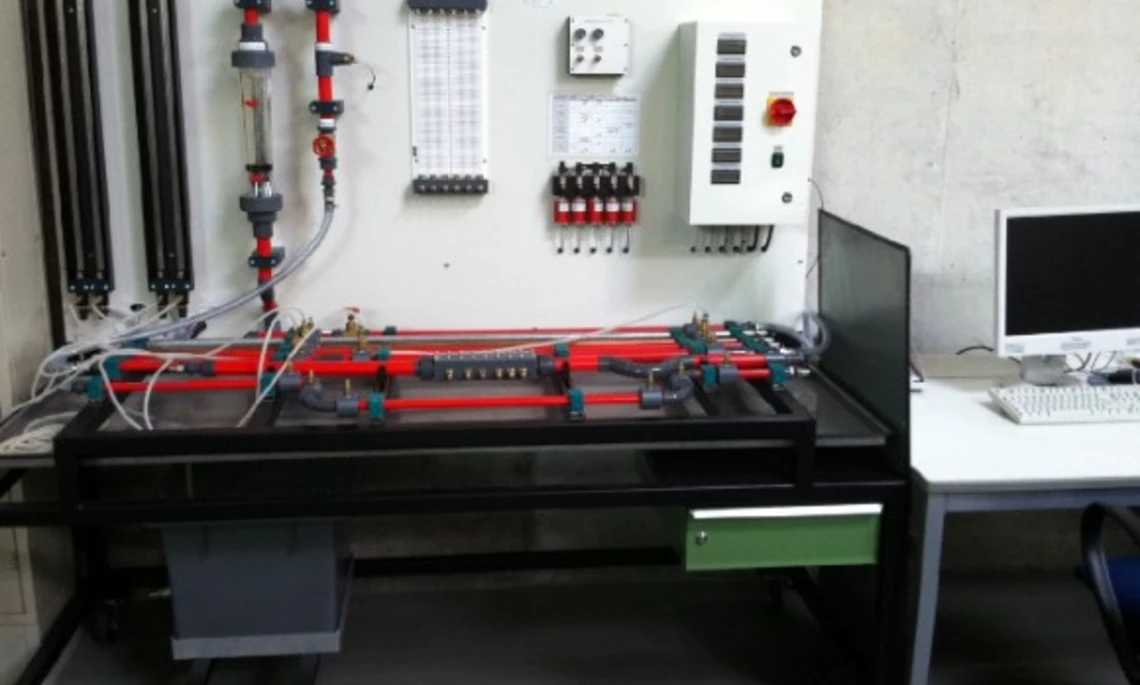

- Hydraulic test bench (GUNT HM 112, Link: https://www.gunt.de/en/products/fluid-mechanics-trainer/070.11200/hm112/glct-1:pa-148:pr-527)

- Shallow water channel (measuring distance: L x W x H =1300mm x 1000mm x 90mm)

- Water turbine (Kaplan; 100mm axial-pump turbine made by Gilkes & Gordon Ltd. London, motor-generator: P_nominal=2.2kW, n=0-3000 rpm, pump-turbine: efficiency_pump=0.6, efficiency_turbine=0.48, PTurbine=350W, feed pump: P-motor=3.0kW, n=970 or 1180 rpm)

- Combined heat and power unit with absorption chiller and heat storage and solar system test bench for combined heat, power and cooling (Energieanlagenbau GmbH Westenfeld, CHP (liquid gas engine) with 17kWel and 32kWth, liquid gas tank 2000L, solar thermal system with 30m² on the roof of building C, heat storage 1500L, absorption chiller 15kW refrigeration capacity, cooling via cooling tower)

- Solar thermal test bench: "Sun simulator" (sun simulator for indoor measurement of solar thermal collectors according to DIN EN 12975-2; connected load: 35kWel)

- Heat storage tank test bench (heat storage tank and system test bench for heat storage tank measurement, e.g. according to DIN 4708 or EN 12977, as well as for the simulation of building heating systems)

- Simulation PCs (six) for simulation calculations, especially CFD (STAR-CCM+ and OpenFOAM v3.0.1)

- Calorimeter

- Apparatus for determining the thermal conductivity

- Convection test bench

- Apparatus for determining the vapour pressure curve

- Pilot plant for distillation/rectification

- Gas turbine (sectional model, for illustration, schematic)

- Fuel cell test bench (for illustration, schematic)

- Solar cooker (parabolic mirror)

Measurement technology:

- Force and moment measurement:

- 3-component balance (2x forces and 1x torque) at the wind tunnel

- 6-component balance on the wind tunnel

- Speed measurement technology:

- Prandtlsonde mounted on the wind tunnel,

- Hand-held measuring devices: impeller anemometers and hot-wire anemometers

- Particle Image Velocimetry (PIV) measurement technology (Dantec Dynamics)

- Hot-wire measurement technology (SVMtec)

- Pressure measurement technology:

- Station Barometer

- Multi-tube pressure gauge

- Primary pressure gauge

- Pressure hand-held measuring instrument

- Flow visualization with smoke lance (multi-hole probe) and smoke wire

- 3D laser scanner

- Thermal imaging camera

- pH and conductivity measuring instrument

Practical trainings accompanying the lectures

- Fluid Mechanics

- Thermodynamics

- Power Engineering

- Aerodynamics

- Flow simulation for engineering applications (BA)

- CFD-FEM (Master)

- Engineering practical training

- Vehicle Aerodynamics

- Environmental Technology

Study projects:

- Aerodynamic doping in sport (2009)

- Brake Energy Regeneration (2011)

- Surfing on river waves (2012) (Ingolstadt Danube surf wave)

- Aircraft/Nurrow wings (2013)

- Stratospheric balloon (2014)

- Rain-Shield (2015)

- Hovercraft (2016)

- Artificial tornado (2017)

- Theses (Bachelor & Master)

- Industrial Projects

- Special events: e.g. university information days, Girls Day, Technology Day, school classes

Laboratory management and team

Prof. Dr.-Ing. Konrad Költzsch

Phone: +49 841 9348-7900

Room: A215

E-Mail: Konrad.Koeltzsch@thi.de

Prof. Dr.-Ing. Sabine Bschorer

Phone: +49 841 9348-3870

Room: A201

E-Mail: Sabine.Bschorer@thi.de

Prof. Dr.-Ing. Wilfried Zörner

Phone: +49 841 9348-2270

Room: A222 S407

E-Mail: Wilfried.Zoerner@thi.de

Phone: +49 841 9348-3420

Room: A121

E-Mail: Markus.Goldbrunner@thi.de

Prof. Dr.-Ing. Tobias Schrag

Phone: +49 841 9348-2820

Room: A228

E-Mail: Tobias.Schrag@thi.de

Phone: +49 841 9348-2761

Room: A115

E-Mail: Daniel.NavarroGevers@thi.de

Prof. Dr.-Ing. Armin Soika

Phone: +49 841 9348-4700

Room: A228

E-Mail: Armin.Soika@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)