The Laboratory for Engine and Automotive Engineering is a proportionate response to the university's orientation towards mobility. Students of different courses of study have the opportunity to experimentally pursue scientific questions in the field of combustion engines and vehicle analysis and to deepen their knowledge of the subject matter in a practical way.

Goals and idea

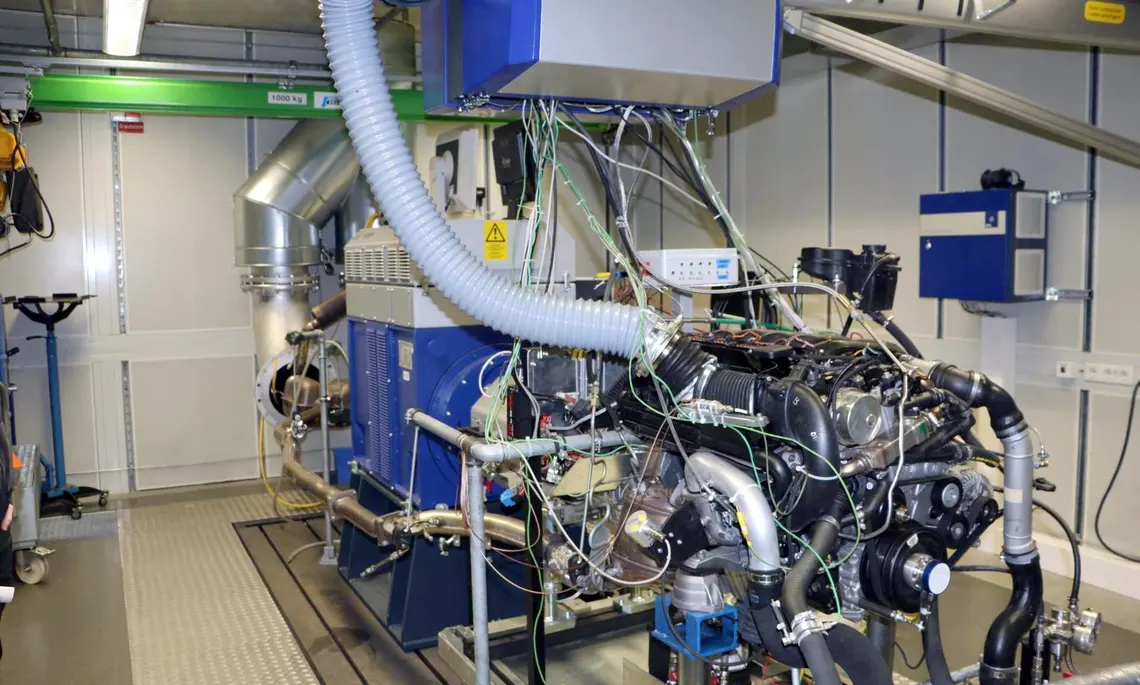

Due to extensive and high-quality equipment, it is possible to operate combustion engines in the power range up to 330kW at different loads and speeds and to carry out thermodynamic analyses or highly accurate fuel consumption measurements and to determine exhaust emissions. In addition, the laboratory has an all-wheel drive roller test bench, which can be used to analyse the operating behaviour of complete vehicles with different drive systems (combustion engine, electric motor, hybrid). For vehicle manufacturers, the chassis dynamometer is an indispensable development tool, the benefits and possible applications of which every vehicle engineer should have become familiar with during his training.

Laboratory equipment and activities

The laboratory has 2 engine test benches, a roller test bench, a component test bench for auxiliary units, as well as two standardized fuel test engines.

The essential technical data are listed below:

- Engine test bench 1: asynchronous machine 330kW, 1400Nm, 8000 rpm, AVL Puma

- Motor test bench 2: asynchronous machine 250kW, 718Nm, 10000 rpm, AVL Puma

- Roller test bench: double roller all-wheel drive, 2*220kW, 10kN traction force (currently being modernized)

- Component test bench: 2*30kW, 6000 rpm, air conditioning hood 10 - 100°C

- Exhaust gas measurement technology: Horiba Mexa 7000, FSN soot measuring device

- Consumption measurement technology: AVL Fuel Mass Flow Meter, AVL KMA mobile

- Indication measurement technology: numerous Kistler sensors and amplifiers, AVL Indimaster

- Fuel test engines: BASF Diesel (DIN 51773), CFR ROZ test engine (DIN EN ISO 5164)

Experimental vehicles:

- Audi TT 2.0 TFSI, BMW M5

Extract from the existing software (for teaching and research purposes):

- AVL Puma Open: Automation software for test benches

- AVL Concerto: data analysis and processing

- GT-Power/Suite: Charge exchange calculation (analysis and simulation)

- IMC Devices/ Famos Studio: Measurement data acquisition and evaluation

- Matlab/Simulink: Control and regulation

Practical courses accompanying the lectures:

- Combustion engines 1

- Internal combustion engines 2

- Measurement technology on the combustion engine

- Fundamentals of automotive engineering

- Road tests

- Engine and drive train

- Hybrid drive systems

- Shell Eco competition vehicle

- Classical and alternative fuels for vehicle drives

Other activities:

- Support of the association eta-nol e.V. in the Shell Eco Competition

- Theses (Bachelor & Master)

- Development of new engine test methods for fuel evaluation

- Development of an innovative micro combined heat and power unit based on a free piston engine

- Competitive analyses of engines, transmissions and auxiliary units

Laboratory management and team

Prof. Dr.-Ing. Karl Huber

Phone: +49 841 9348-3820

Room: A123

E-Mail: Karl.Huber@thi.de

Phone: +49 841 9348-3880

Room: A203

E-Mail: christian.vonperponcher@thi.de

Phone: +49 841 9348-3690

Room: A123

E-Mail: Joerg.Kessler@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)