Biogas plants are indispensable for the future energy supply with renewable energies due to their flexible and controllable application possibilities. The interaction of biogas and hydrogen can significantly increase this flexibility. Therefore, the research project "FlexBiomethane" investigates methane enrichment by direct catalytic methanation of biogas with hydrogen. To this end, the Institute for New Energy Systems (InES) at Technische Hochschule Ingolstadt (THI) is working closely with the Chair of Energy Process Engineering at Friedrich Alexander University Erlangen-Nürnberg (FAU) and the company Regineering GmbH.

The biogas produced by the biogas plant usually consists of 50 % methane and 45 % carbon dioxide. In addition to these main components, biogas also contains other components such as nitrogen, hydrogen sulfide or hydrogen. However, only the combustible methane can be used to generate energy in a Combined heat and power plant (CHP). The other components of the biogas are not needed for energy production, but they consume the "space" in the gas storage of the biogas plant.

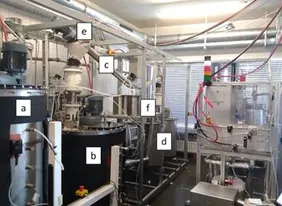

The aim of the project is therefore to replace the place of carbon dioxide in the existing gas storage with methane and thus to use the gas storage more efficiently. For this purpose, the carbon dioxide content in the biogas is converted into synthetic methane by means of catalytic direct methanation using the FAU reactor, which was developed in-house and manufactured using a 3D printing process, and the addition of hydrogen. The possible methane enrichment in the gas storage is examined on the basis of an experimental test series in the biogas laboratory of the THI.

At the beginning of June, it was possible for the first time to couple the FAU methanation reactor with the THI laboratory biogas plant and operate it as an overall process. Project leader Professor Markus Goldbrunner: "The first results are promising. Through the reactor, a methane enrichment of the real biogas up to 90 % could be achieved." Methane enrichment up to more than 80 % could also be demonstrated in the gas storage of the biogas plant. The major advantage of this described storage concept compared to conventional plants is that no complex biogas upgrading with CO2 capture is required for methanation. The storage system is thus designed as a retrofit option for existing biogas plants.

The FlexBiomethane project is a research project funded by the “Fachagentur Nachwachsende Rohstoffe e. V.” and the “Bundesministerium für Ernährung und Landwirtschaft” and supported by the three project partners mentioned above. The project was started at the beginning of 2020 and is designed to run for three years.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/0/csm_20220726_InES_Reaktor_Korrektur_mit_gruener_markierung-Flexbiomethane_Versuchsstand_der_FAU_71215070da.webp)

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)