At our research group, we have developed an automatic panel level TTA tester. The tester targets to ease TTA during reliability assessment and for production inspection. The LED panel is placed on the temperature stabilized table of a xyz-system.

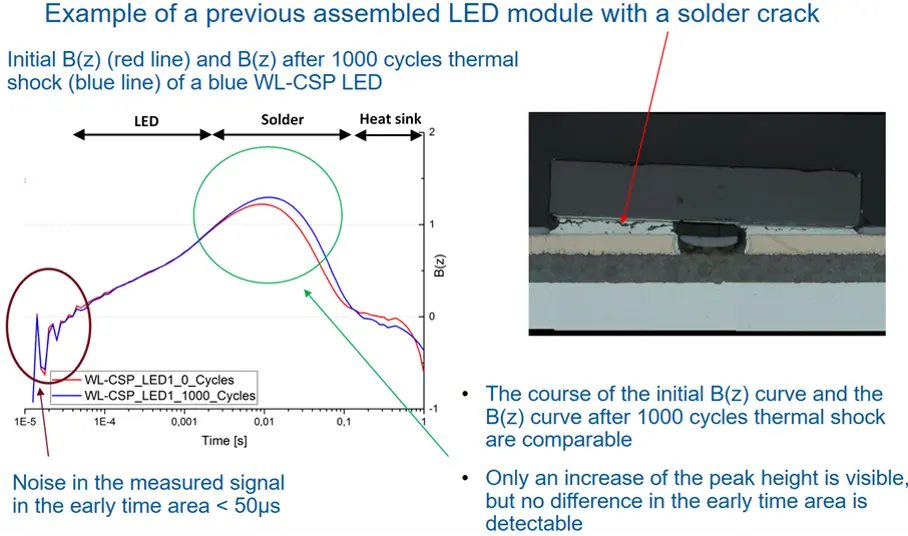

The position of the electrical test pads of the LEDs are read into the machine from Gerber data. The measurement electronics is mounted on the xyz-system to enable the use of short cables with low parasitic inductance. The LEDs are contacted by 4-point probes. To resolve the thermal resistance between the LED die (first level interconnect) and the substrate the forward voltage of the LEDs after current switching need to be measured as early as possible, i.e. well below 10μs. The developed current source allows very fast switching within 100ns and stabilize the detection current within less than 5μs. To evaluate the thermal path and the thermal resistance the relative thermal resistance measurement method is applied.

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)