Focus:

- Insulation testing on electrical traction machines

- Localization of insulation faults using partial discharge detection

- Identification and elimination of disturbing influences during partial discharge testing in the production line

Summary:

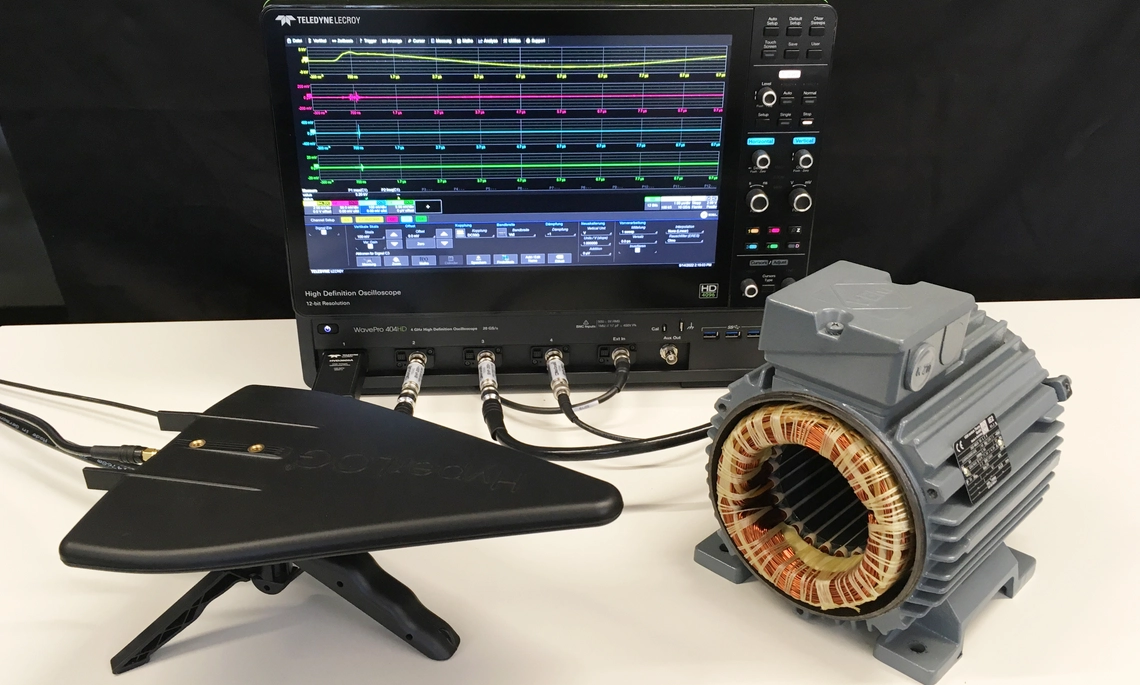

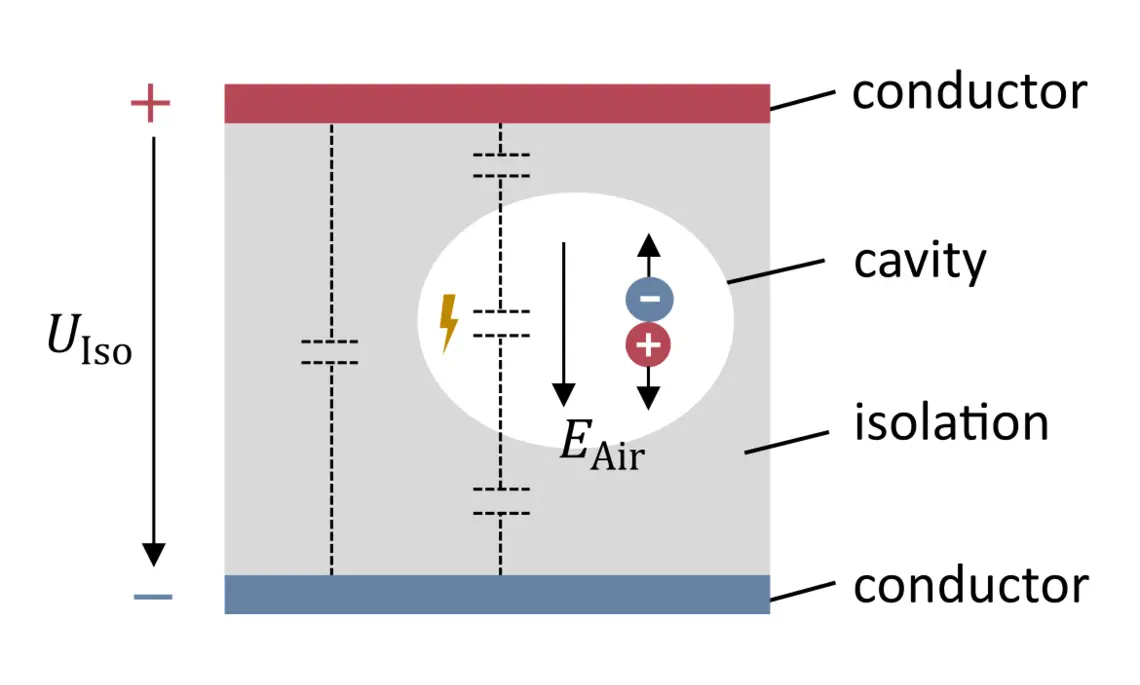

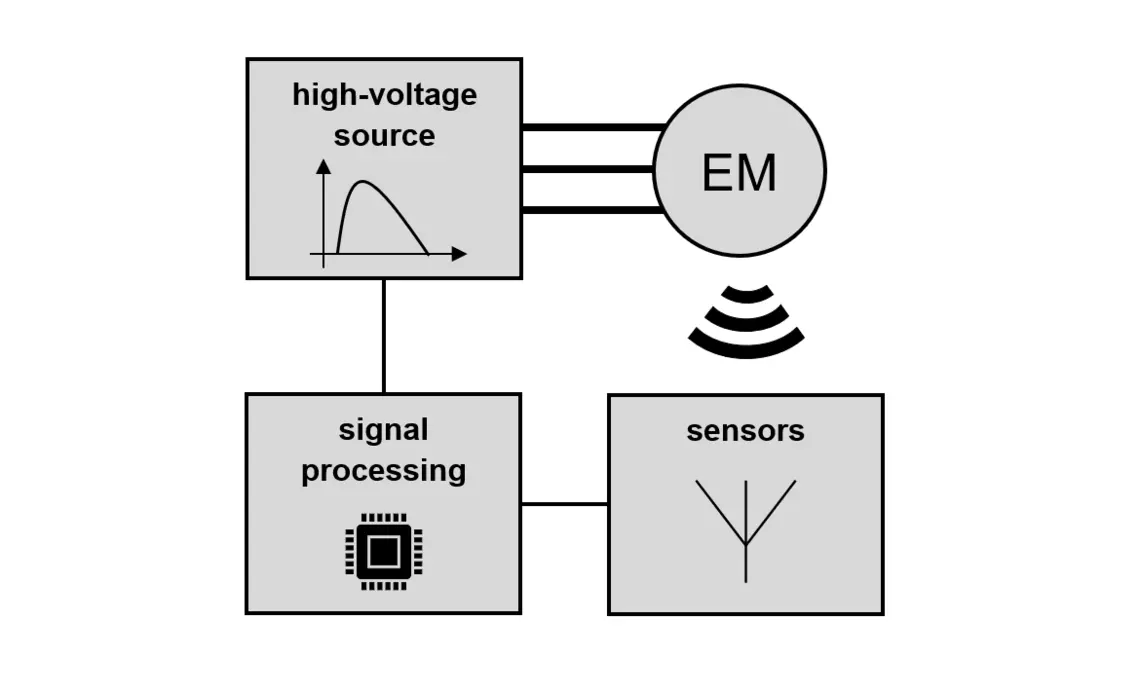

The insulation system of traction machines in electric vehicles is exposed to high electrical stress due to fast switching inverters. Nevertheless, the insulation material has to ensure a safe separation of the individual windings over the entire vehicle lifetime. Exceeding a critical field strength, an avalanche-like ionization mechanism can start at weak spots in the insulation, such as air pockets. The consequence of this process is a partial breakdown of the insulation. The repeated occurrence of these so-called partial discharges (PD) erodes the surrounding insulation material and causes a premature failure of the electrical machine. Therefore, PD testing of the insulation system has great importance in terms of quality control in the production line. The test objects are subjected to a certain high voltage. When partial discharges occur, electromagnetic waves are radiated as a result of high frequency compensation currents. Consequently, one possibility for detecting PD is sensing the emitted spectrum.

Within the scope of this research project, disturbing influences during PD testing on electrical stators are investigated in order to reduce unnecessary component rejects. Accuracy and reproducibility of the test procedure should be increased by means of suitable sensor technology and evaluation algorithms.

Relevant literature:

- A. Rauscher, M. Hufnagel, C. Endisch, Pareto optimization of wavelet filter design for partial discharge detection in electrical machines, Measurement, Volume 205 (2022). https://doi.org/10.1016/j.measurement.2022.112163.

Contact

Andreas Rauscher, M. Eng.

Phone: +49 841 9348-4152

Room: S421

E-Mail: Andreas.Rauscher@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)