The Laboratory for Bioenergy Technology is concerned with current issues concerning the supply of energy from renewable resources. The focus is on making energy production more flexible, biogas plant technology and biogas processing and utilisation. In the practical trainings of the bachelor course "Energy Technology and Renewable Energies" as well as the master course "Renewable Energy Systems", experiments on the combustion of biomass or basic principles of thermodynamic (cycle) processes are carried out, among other things.

Goals and idea

The laboratory is integrated into the Institute for New Energy Systems (InES), in which all research activities in the fields of bioenergy technology, energy system technology and solar energy technology are combined. The application-oriented research projects are mainly carried out in cooperation with medium-sized industrial partners as well as with research institutes and partner universities.

Laboratory equipment and activities

- Practical training of students in the field of bioenergy technology

- Technical and ecological-economic plant optimisation of biogas production

- Development and investigation of flexible energy supply by biogas

- Thermal and process engineering simulation of thermodynamic cycle processes

- Analysis and investigation of wood-fired power plants

- Basic research on biogas processing and utilisation

- Simulation and process control of biogas plants

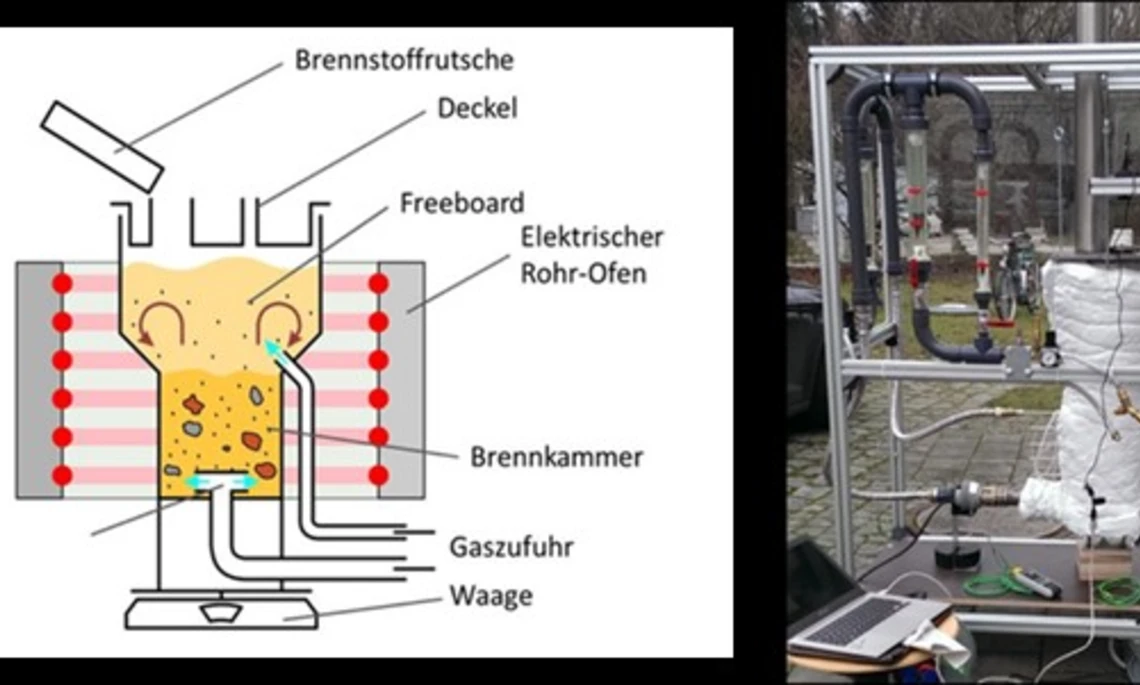

Combustion and pyrolysis test bench

The compact and mobile experimental plant allows a comprehensive insight into the combustion and gasification of (solid) biomass, especially during practical training. The influence of the variable air supply on the pollutants in the flue gas can be worked on in detail by the students during the practical course by means of experiments and measurements. In addition, the dependence of the pyrolysis reaction rate on temperature can be measured.

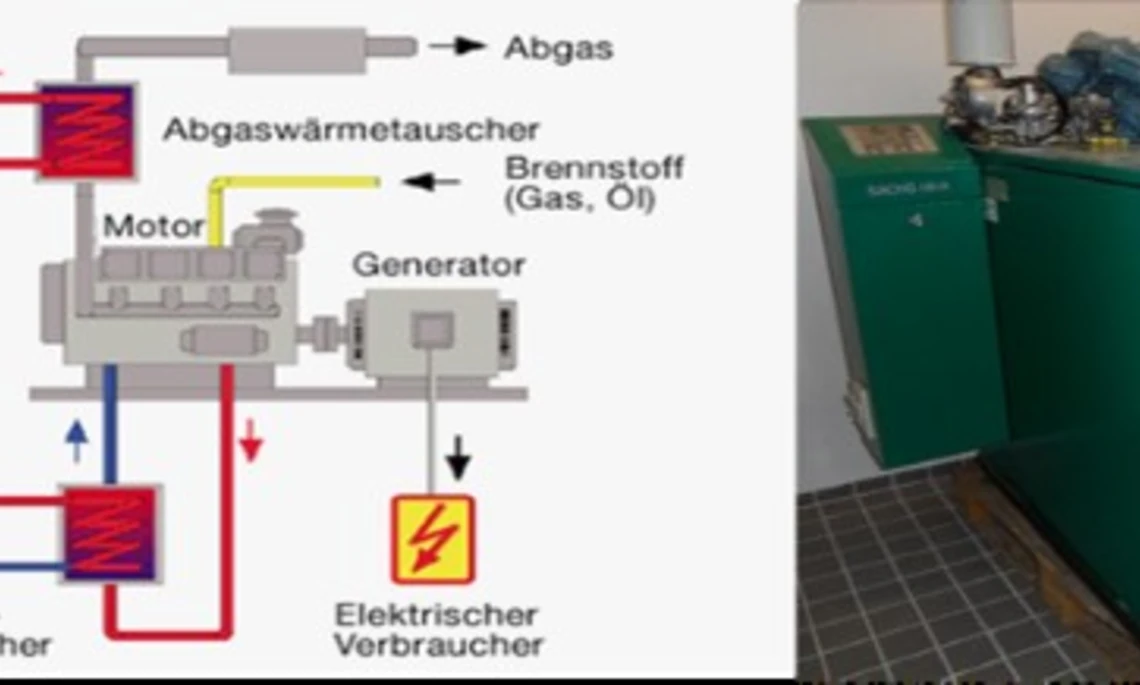

Combined heat and power unit

A combined heat and power unit (CHP) is a modular system for the generation of electrical energy and heat, which is preferably operated at the place of heat consumption. It can also feed useful heat into a connected local heating network. A mini CHP unit (type HKA-R S1) from the company SenerTec is to be used in the planned practical trial. A combined combustion process of biogas and light fuel oil is used to generate energy by the igniting jet engine. In the practical test, the CHP unit is to be examined in terms of energy at different load points. In addition, the exhaust gas composition can be investigated.

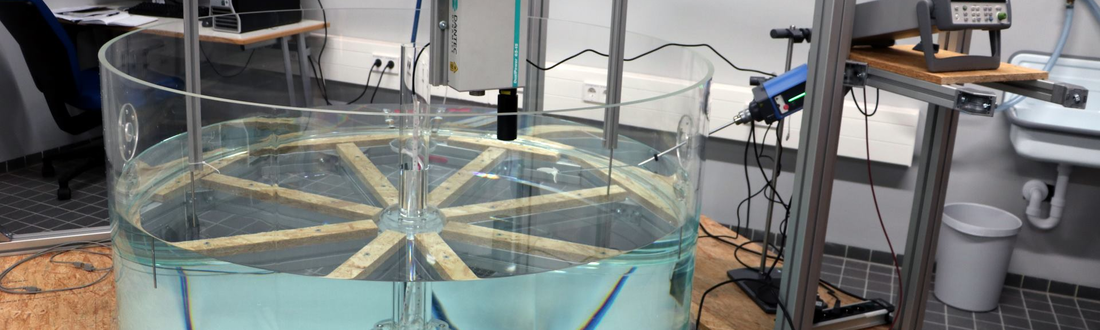

Laboratory biogas plant

With the laboratory biogas plant, students can learn the basic principles of biogas production in a practical way. This includes, among other things, the general functioning of a biogas plant, the interaction of the various components, the necessary measurement and control technology, as well as the effects of substrate composition and temperature on biogas production and the real behaviour of the biogas plant on various disturbance variables. The laboratory biogas plant can be operated both in two stages and in parallel by means of two serially operable containers. In addition, the plant also allows detailed scientific investigations - e.g. for agitator optimisation and flexibilisation.

Wood-burning and pellet stove

With the chimney and pellet stove the combustion of solid fuels in the small power range (up to 10kW) is visualized and measured by an exhaust gas analyzer. The chimney and pellet stoves allow the separate adjustment of the supply of primary and secondary air. In the wood-burning stove it is possible to burn not only logs but also other fuels such as wood or lignite briquettes. Oxygen (O2), carbon monoxide (CO) and nitrogen oxide (NOX) concentrations are measured and visualised via flue gas analysis in order to be able to assess the "quality" of the combustion. In addition to the air supply, other factors influencing emissions can also be investigated for different fuels or heating or fuel supplied processes.

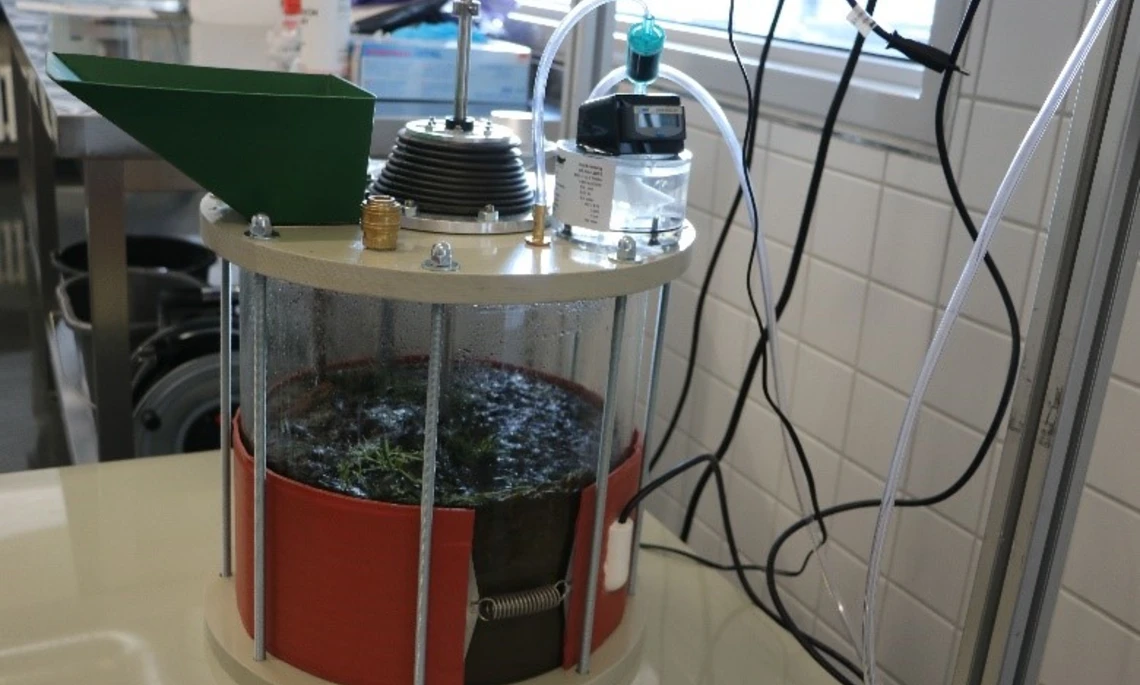

Fermentation tank

A mobile fermentation tank (10l) with a simple propeller stirrer and heating by means of a sleeve was set up to demonstrate and visualise gas production by fermentation of biomass in practical training.

Different influencing variables on the process of biogas production, such as temperature, digester load and mixing can be investigated.

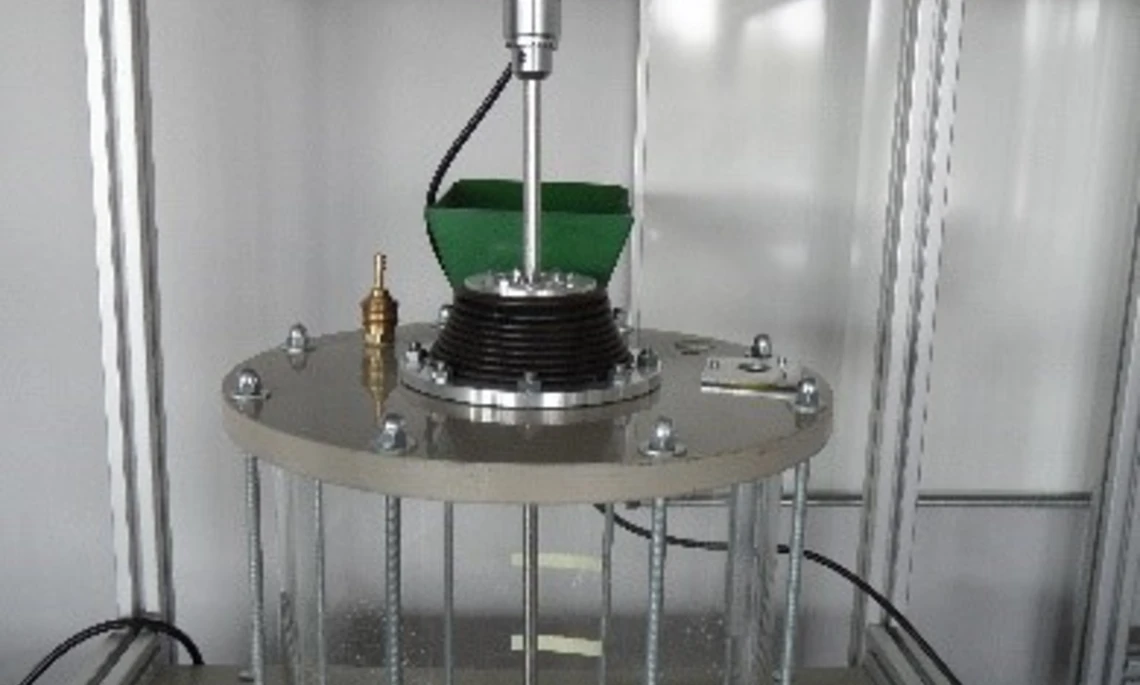

Eudiometer

Using the eudiometer from Selutec, the quantity and composition of the biogas produced can be determined by fermenting bioactive substrates. To do this, the eudiometer is completely filled with liquid and its open end is immersed in a bath of the same liquid (water). Water is displaced from the eudiometer due to a chemical reaction that produces fermentation gases in the tempered substrate. The volume of displaced liquid corresponds to the volume of the (bio) gas produced.

Steam power plant

With the Gunt practical test stand the behaviour of steam power plants under different operating conditions can be examined and understood. Due to the use of real components, aspects such as maintenance, repair, measurement, control and regulation technology can also be taught. The test setup consists of two test bench parts:

- Steam generation: completely functional small steam generator with gas-fired instantaneous boiler and closed water circuit

- Steam turbine: single-stage axial impulse turbine

- Drying oven (memmert UFE500)

- Incinerator (Nabertherm, LVT5/11/P330)

- Mobile gas analysis system (Binder Engineering, COMBIMASS GA-m)

- Exhaust gas analyser (testo 340)

- Simulation software SIMBIA

- Simulation software EBSILON

- Bioenergy Technology

- Plant engineering solid fuels

- Energy conversion in power and working machines

- Thermodynamics

- Design and CAD

- Improvement of mixing in biogas fermenters through methodical agitator optimisation (BIOOPT-MIX)

- Integration of biogas plants in networks with a high proportion of fluctuating power generators (FlexFuture)

- Innovative steam storage concepts for decoupling power plant control and electricity production

- Scientific and technical evaluation of the potentials of the energy-efficient use of the thermal energy obtained from wood chips in the context of combined heat and power generation

- Experimental investigation of the flow behaviour of agitators in biogas fermenters

- Biogas on the move: Investigation of the feasibility of decentralised use of partially upgraded biogas as fuel for agriculture

Laboratory management and team

Phone: +49 841 9348-3420

Room: A121

E-Mail: Markus.Goldbrunner@thi.de

Dipl.-Ing. (FH) Leslie Bauer

Phone: +49 841 9348-4410

Room: C026

E-Mail: Leslie.Bauer@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)