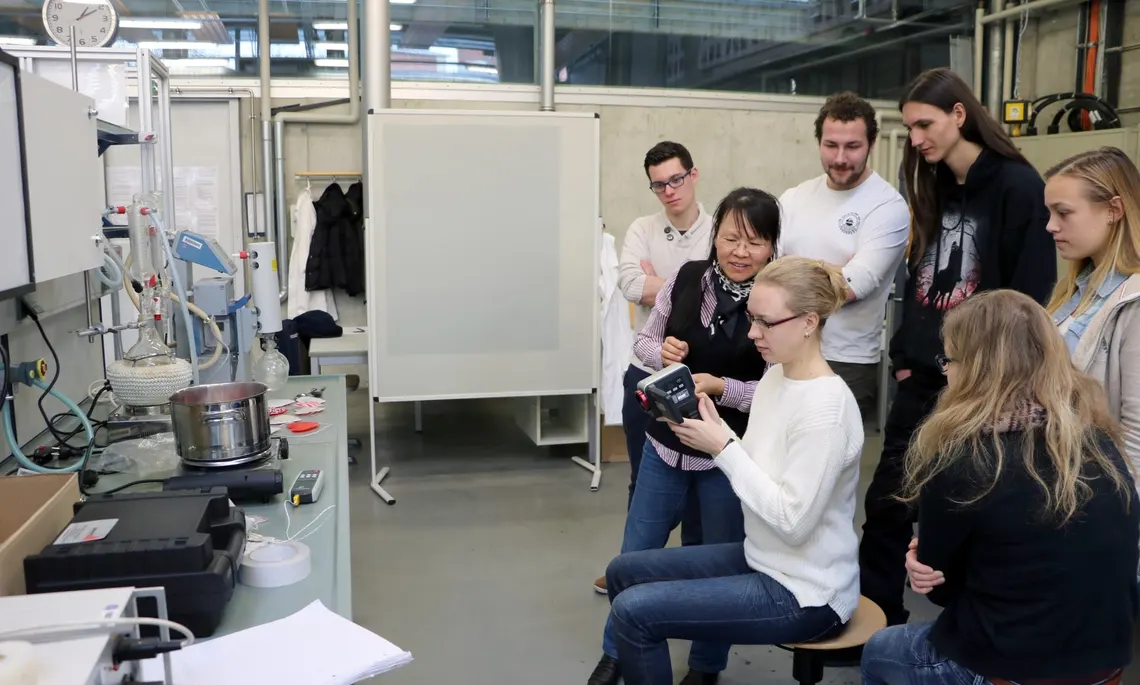

The Laboratory for building energy technology is concerned with the fields of air conditioning technology, heating technology, local heating systems, building physics and storage technology. In the practical trainings of the bachelor's programme "Energy Technology and Renewable Energies" as well as the master's programme "Renewable Energy Systems", among other things, experiments are carried out on the hydraulic balancing of heating circuits or the basics for drawing up energy balances.

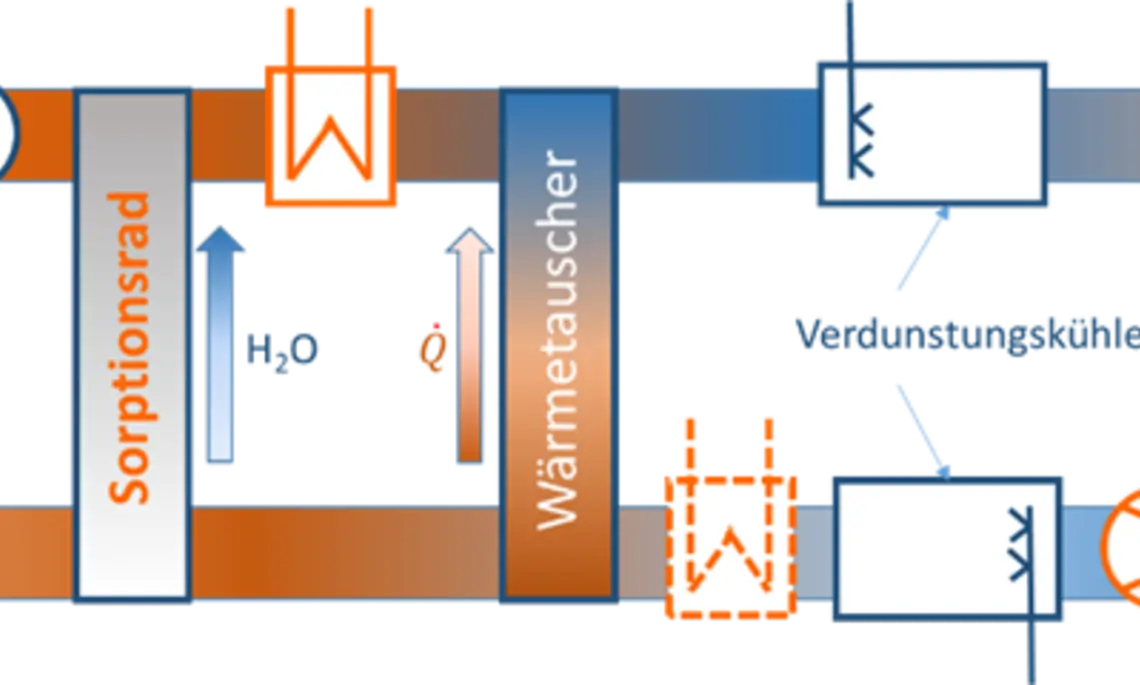

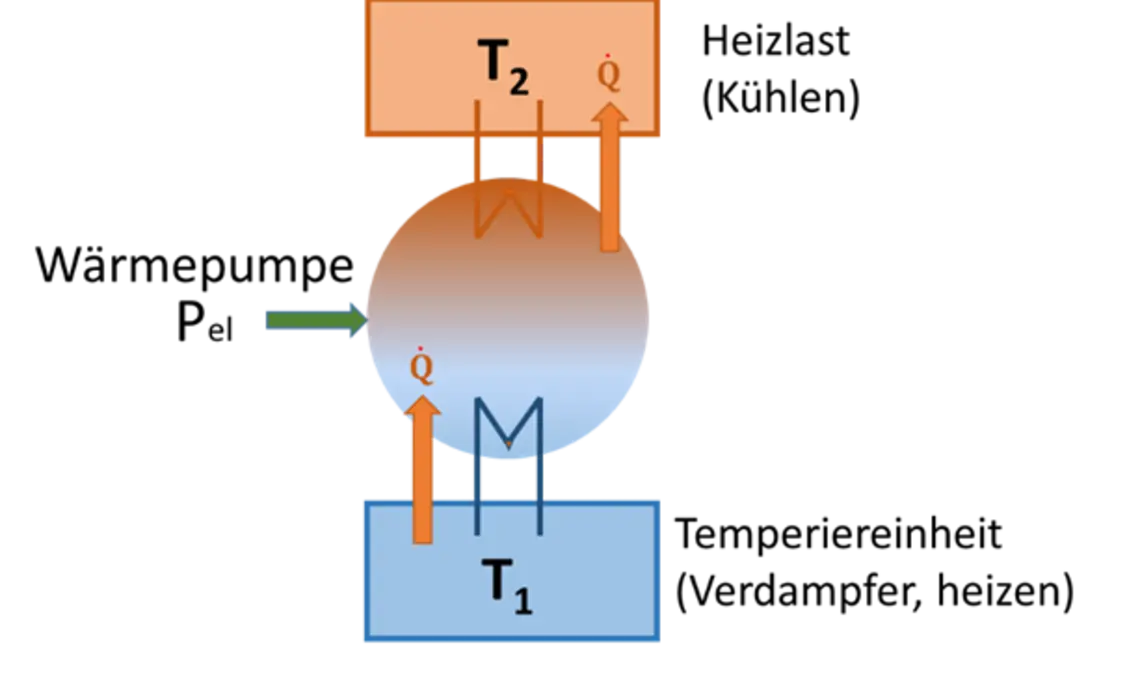

With a view to the intended research focus, the construction of a heat engineering test bench for heat pumps, heat transfer stations and heat storages have been built and are already used in several research projects. Heat pumps represent an interesting possibility for the intelligent linking of electricity and heat supply in residential buildings. By means of grid-controlled heat pump operation, a bridge can be built to grid-reactive buildings, which will become increasingly important in future for stabilising the electricity grid.

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)